Have you ever wondered why most of the instruments in a laboratory gleam with the clarity of glass? Why, despite the plethora of materials available, does glass dominate the benches of our scientific sanctuaries?

Glass is not just a material; it’s a cornerstone of scientific inquiry. Its unmatched transparency, chemical stability, and heat resistance make it the go-to choice for laboratory instrument design. This article delves into the reasons behind glass’s supremacy in labs across the globe.

We often take for granted the clear, sturdy vessels that hold our most volatile experiments. But why is glass the unspoken hero of the lab?

Why is Glass an Ideal Material for Making Laboratory Instruments

Glass is an inorganic, non-metallic material with a variety of excellent properties, making it extensively used in the manufacturing of laboratory instruments. The reasons why glass is an ideal material for this purpose are:

- Chemical Stability: Glass has good chemical stability and does not easily react with chemical reagents, making it suitable for manufacturing various chemical experimental instruments.

- Transparency: Glass has high transparency, allowing convenient observation of experimental reactions and results.

- Heat Resistance: Glass has good heat resistance and can withstand temperature changes within a certain range, making it suitable for heating and cooling processes in laboratories.

- Mechanical Strength: Glass has a certain level of mechanical strength, is not easily deformed or damaged, and can ensure the precision and stability of experimental instruments.

- Electrical Insulation: Glass has good electrical insulation properties, does not produce static electricity or conduct electricity, and is therefore suitable for electrical experiments in laboratories.

- Production Cost: The production cost of glass is relatively low, making it easy to process and manufacture, suitable for mass production of laboratory instruments.

- Reusability: Glass laboratory instruments can be cleaned and sterilized for reuse, which helps save resources and reduce experimental costs.

- Safety: Glass is a relatively safe material, not producing harmful chemicals or radioactive substances, and is therefore suitable for various experiments in the laboratory.

Which Type of Glass is Most Suitable for Making Laboratory Glassware

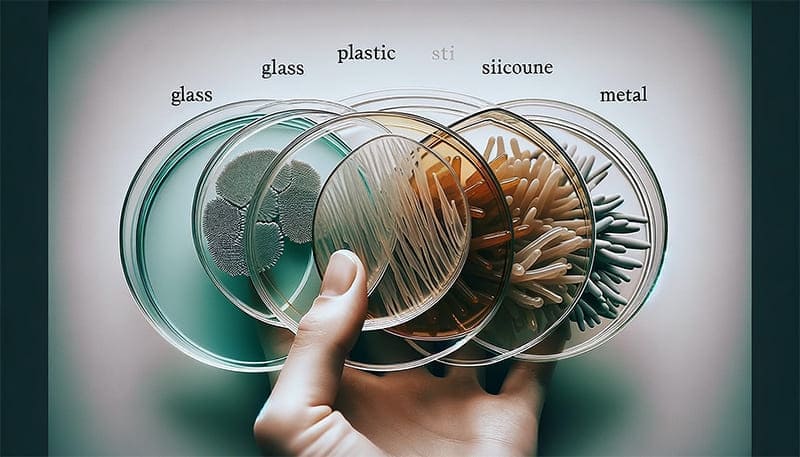

When creating laboratory instruments, glass materials that are heat-resistant, chemically resistant, highly transparent, easy to clean, and not easily deformed are usually chosen. Here are several common types of glass materials, along with their characteristics and applications:

- Borosilicate Glass: This type of glass has extremely high heat and chemical corrosion resistance. It is commonly used to make heat-resistant test tubes, beakers, and bottles in laboratories. Not only does it have high thermal stability, but it also resists corrosion by most laboratory chemicals.

- Quartz Glass: Mainly composed of high-purity silicon dioxide, quartz glass has very high heat resistance, chemical corrosion resistance, and translucency. It is suitable for making chemical and optical instruments used under high temperature and pressure. Due to its high purity and stability, quartz glass is a common choice for high-temperature and chemical experimental instruments.

- Molybdenum Silicate Glass: Composed mainly of silicon dioxide and molybdenum oxide, this glass has extremely high resistance to high temperatures and chemical corrosion. It is suitable for making chemical instruments used under high temperature and pressure. Its excellent high-temperature resistance makes it suitable for high-temperature reactions and chemical analysis in laboratories.

- Alumina Glass: With aluminum oxide as its main component, this glass has extremely high heat resistance and corrosion resistance. It is suitable for making chemical instruments and furnaces used at high temperatures. Its high heat and corrosion resistance make it an ideal material for various instruments in the laboratory.

Besides these, there are other types of glass materials like sodium calcium glass and high borosilicate glass, which also have good heat resistance and chemical stability, suitable for laboratory instrument fabrication. However, the specific choice of glass material needs to be based on specific experimental requirements and usage scenarios. For instance, borosilicate glass or quartz glass is often chosen for instruments that need to withstand extremely high temperatures; molybdenum silicate glass is selected for high-pressure instruments; and alumina glass or high borosilicate glass for instruments requiring very high corrosion resistance.

When selecting glass materials, it is necessary to consider the experimental requirements and usage scenarios comprehensively. Additionally, attention should be paid to the cleaning and maintenance of the instruments to ensure the accuracy of experimental results and laboratory safety.

Challenges and Limitations of Glass in Laboratories

While glass is a highly valued material in laboratory settings, it is not without its challenges and limitations. One significant concern is the durability of glass in certain scenarios. Despite advancements in strengthening treatments, glass is inherently fragile and can break under impact or when subjected to extreme temperature changes. This fragility poses risks in terms of both safety and potential contamination of experiments.

Another notable limitation is the cost associated with specialized types of glass. While standard glassware like borosilicate is relatively affordable, more specialized types, such as quartz or alumina glass, come with a higher price tag. These costs can be a significant factor for budget-conscious laboratories, particularly in educational settings or in developing countries.

Additionally, there are limitations in terms of chemical compatibility. Even though glass is generally chemically inert, certain types of glass can react with or be degraded by specific chemicals. For instance, hydrofluoric acid is known to etch glass, and some alkaline solutions can slowly degrade glass surfaces over time. This necessitates careful selection of glassware based on the specific chemicals used in experiments.

In response to these challenges, the scientific community and glassware manufacturers are continually exploring alternatives and improvements. These include the development of more durable glass composites, coatings that enhance chemical resistance, and designs that minimize breakage risk. Additionally, proper handling, storage, and training can mitigate some of these limitations, extending the life and effectiveness of glass instruments.

Despite these challenges, the unique combination of transparency, chemical inertness, and thermal resistance continues to make glass a highly sought-after material in laboratory environments. However, it’s important to acknowledge these limitations and consider them when choosing the appropriate materials for specific laboratory applications. This balanced approach ensures the safety, efficiency, and cost-effectiveness of laboratory operations.

Global Market Trends and Demand in Laboratory Glassware

The global market for laboratory glassware has witnessed significant growth, driven by several key factors. One of the primary drivers is the increasing investment in research and development (R&D) activities across various sectors. As scientific research becomes more advanced and intricate, the demand for high-quality and specialized laboratory glassware rises. This is particularly evident in industries such as pharmaceuticals, biotechnology, and environmental testing, where precise and reliable glass instruments are indispensable for daily operations.

Another significant factor contributing to the growth of the laboratory glassware market is the expansion of the educational sector, especially in higher education and research institutions. Universities and colleges are investing more in science and engineering programs, leading to a higher demand for laboratory glassware for teaching and research purposes. Glassware’s durability, reusability, and safety make it a preferred choice in educational laboratories where hands-on experiments are fundamental to the learning process.

The pharmaceutical sector, in particular, has seen an increased demand for laboratory glassware due to the ongoing development of new drugs, vaccines, and treatment methods. The stringent quality control measures and regulatory requirements in pharmaceutical research necessitate the use of reliable and contamination-free glassware. Borosilicate glass, known for its thermal and chemical resistance, remains a popular choice in this sector.

Furthermore, the growth in environmental monitoring and testing services has also spurred the demand for laboratory glassware. Glass’s resistance to chemicals and its non-reactive nature make it ideal for collecting and analyzing environmental samples, such as water, soil, and air pollutants.

In addition to these sectors, the advancement in technology and the introduction of innovative glassware designs tailored for specific research needs are also contributing to the market growth. Manufacturers are continuously improving glassware for better safety, accuracy, and convenience, thereby catering to the evolving needs of modern laboratories.

Overall, the laboratory glassware market is expected to continue its growth trajectory, supported by the ongoing advancements in science and technology, the increasing importance of R&D activities, and the expansion of educational and pharmaceutical sectors globally. This trend underscores the continuing supremacy of glass in the world of laboratory instruments, reflecting its irreplaceable role in the advancement of science and education.

Conclusion

“Why Glass Reigns Supreme in Laboratory Instruments Design” not only illuminates the enduring legacy of glass in scientific endeavors but also underlines its evolving role in modern laboratories. As we continue to push the boundaries of research and technology, the versatility and reliability of glass remain integral. Let us embrace this clear path to discovery, ensuring that our scientific pursuits are grounded in materials that have stood the test of time. Join us in celebrating glass, a true pillar of laboratory innovation.