Have you ever noticed the distinctive amber glassware in a laboratory and wondered about its purpose? Beyond its aesthetic appeal, this amber glassware serves a critical function in scientific research. It’s not just a container; it’s a shield, safeguarding sensitive solutions from harmful external factors.

Brown lab glassware, commonly referred to as amber glass, is essential for protecting light-sensitive materials. This tinted glass acts as a barrier against certain wavelengths of light that can degrade or alter the composition of various chemicals and solutions. This protection is particularly crucial in fields like pharmaceuticals, biochemistry, and environmental science.

Let’s delve into why this seemingly simple choice of color is a cornerstone in the preservation of sensitive substances.

Why Opt for Amber Glass in Laboratories

The primary role of amber glassware is to protect photosensitive compounds from light, particularly UV and blue light. Light-sensitive chemicals, including certain drugs, vitamins, and reagents, can undergo detrimental changes when exposed to light. These changes can affect their potency, efficacy, and safety. Amber glass efficiently filters out harmful light rays, ensuring the stability and longevity of these substances.

Understanding the Spectrum: How Amber Glass Filters Light

A closer look at the science reveals how amber glass selectively filters light. The amber tint is not just for show; it’s a result of adding materials like iron, sulfur, and carbon to the glass during production. These additives absorb light in the ultraviolet (UV) to visible light range (around 300 to 500 nanometers). This absorption is critical because it’s within this range that light can be most harmful to many chemicals.

The effectiveness of amber glass in blocking light varies depending on the thickness and exact composition of the glass. However, the general principle remains consistent: it significantly reduces the transmission of potentially damaging light rays.

The Interaction of Light with Chemicals

In the realm of chemistry, light can be more than just a source of brightness; it can act as a catalyst for chemical reactions. Ultraviolet (UV) light, with its higher energy, is particularly notorious for causing photodegradation. Amber glass is designed to absorb and block UV and blue light, preventing these harmful light-induced reactions from occurring within the bottle.

The Efficacy of Amber Glass

Research indicates that amber glass can block significant amounts of UV and blue light, often up to 99%. This level of protection is vital for preserving the integrity of various light-sensitive substances. Pharmaceuticals, essential oils, and biological samples, for instance, can maintain their properties and effectiveness for an extended period when stored in amber glassware.

Applications of Amber Lab Glassware

The utilization of amber glassware is particularly critical for:

- Light-Sensitive Chemical Reagents in Laboratories: Various chemical reagents used in laboratory settings are sensitive to light and require protection to maintain their stability and reactivity. Amber glassware is essential for storing these reagents to prevent light-induced degradation or unwanted reactions.

- Pharmaceuticals: Many medications are sensitive to light and can lose their effectiveness or become unsafe upon light exposure.

- Vitamins: Certain vitamins degrade quickly when exposed to light.

- Essential Oils: These natural extracts can lose their therapeutic properties under light exposure.

- Biological Samples: DNA, proteins, and other biological materials can undergo degradation or alteration when exposed to light.

Below is a detailed table outlining specific types of amber laboratory glassware, their applications, and usage guidelines:

Specific Applications of Amber Lab Glassware and Their Guidelines

| Brown Lab Glassware Type | Application | Usage Guidelines |

|---|---|---|

| Amber Vials | Storing small volumes of pharmaceuticals, especially injectables | Ensure tight sealing to prevent contamination; avoid direct sunlight |

| Amber Reagent Bottles | Holding light-sensitive chemical reagents and solvents | Store in a cool, dark place; label clearly to avoid mix-ups |

| Amber Dropper Bottles | Dispensing light-sensitive liquid medications and essential oils | Use dropper carefully to control dosage; keep away from heat sources |

| Amber Reaction Flasks | Conducting photo-sensitive chemical reactions | Shield from direct light sources during reactions; handle with care |

| Amber Storage Jars | Long-term storage of photosensitive biological samples | Keep sealed to avoid exposure to air and moisture; store in stable temperature conditions |

Detailed Analysis of Light-Induced Chemical Reactions and Protection Mechanisms

Mechanisms of Photodegradation

Understanding the mechanisms of photodegradation is crucial in appreciating the protective role of amber lab glassware. Photodegradation occurs when light-sensitive substances absorb specific wavelengths of light, leading to chemical reactions that can alter their molecular structure and properties. This process is particularly pronounced with ultraviolet (UV) and certain visible light wavelengths, which possess enough energy to break chemical bonds.

In the case of pharmaceuticals, exposure to such light can lead to the breakdown of active ingredients, reducing their efficacy or potentially forming harmful by-products. Similarly, in biochemical solutions like DNA or certain proteins, light exposure can result in structural alterations that impair their function.

Protection Mechanisms

Amber glassware offers a defense against these detrimental effects through its unique light absorption and filtering capabilities. The amber tint of the glass is achieved by incorporating specific additives during the manufacturing process, such as iron oxides, which imbue the glass with its characteristic color. This coloration is not merely for aesthetic purposes; it plays a vital scientific role.

- Selective Light Absorption: The amber coloration of the glass is designed to absorb light in the UV and visible spectrum (approximately 300 to 500 nanometers). This absorption prevents these wavelengths from penetrating the glass and interacting with the substances inside.

- Filtering Harmful Wavelengths: By filtering out the harmful wavelengths of light, amber glassware effectively protects its contents from the initiation of photodegradation processes. This is particularly important for substances that are sensitive to light in the UV and visible range.

- Maintaining Chemical Integrity: By limiting exposure to harmful light, amber glassware helps maintain the chemical integrity and stability of its contents. This is essential for ensuring that pharmaceuticals retain their intended potency and that biological samples remain unaltered for accurate study and analysis.

- Chemical Inertness: In addition to its light-filtering properties, amber glass is chemically inert. This means it does not react with the substances stored within it or contribute to any chemical changes. This inertness is crucial for maintaining the purity and stability of sensitive substances, ensuring that they retain their desired properties and effectiveness over time.

The integration of amber glassware in laboratory settings thus serves as a critical measure to preserve the quality and effectiveness of light-sensitive solutions. Its use is a testament to the intersection of material science and practical application in scientific research, ensuring that sensitive substances are stored and handled under conditions that maintain their integrity and usefulness.

Integration of Amber Glassware in Modern Laboratory Practices

Innovations in Lab Procedures

The introduction of amber glassware has brought significant innovations to laboratory procedures, particularly in fields like photobiology, photochemistry, and pharmaceutical development, where light-sensitive materials are frequently used.

In photobiology, the study of the effects of light on biological organisms, amber glassware has become essential for experiments involving light-sensitive biological samples. For instance, studies on the impact of light on cell growth or photosynthesis often require substances to be stored in conditions that precisely control light exposure. Amber glassware enables researchers to store and handle these substances without the risk of unwanted light-induced reactions, ensuring the accuracy of experimental results.

In the realm of photochemistry, where chemical reactions are initiated by light, amber glassware is used to store reactants and control the timing and extent of light exposure. This precise control is crucial for studying reaction mechanisms and developing new photochemical processes.

In pharmaceutical development, the stability of drugs is a paramount concern. Many drugs are sensitive to light, and their degradation can lead to reduced efficacy or harmful byproducts. Amber glassware is extensively used to store and protect these pharmaceutical compounds, playing a critical role in drug stability tests and ensuring that medications remain safe and effective until they reach the consumer.

Best Practices for Using Amber Glassware

To ensure optimal protection of sensitive solutions, laboratories must adhere to best practices in the handling, storage, and maintenance of amber glassware:

- Proper Storage: Store amber glassware in a cool, dark place to maximize its light-protective properties. Avoid exposure to direct sunlight or intense artificial light sources.

- Handling Precautions: Handle amber glassware with care to prevent breakage. Use gloves and safety equipment as necessary, especially when the glassware contains hazardous or volatile substances.

- Regular Inspection: Regularly inspect amber glassware for any signs of damage, such as cracks or chips, which can compromise its protective qualities. Replace damaged glassware promptly.

- Cleaning and Maintenance: Clean amber glassware thoroughly after each use. Follow proper cleaning procedures, using appropriate solvents and avoiding abrasive materials that can scratch the glass. Ensure the glassware is completely dry before storing or reusing.

- Labeling and Documentation: Clearly label amber glassware with the contents, concentration, and date of storage. Maintain proper documentation for tracking and compliance purposes.

- Training and Awareness: Ensure that laboratory personnel are trained in the proper use and maintenance of amber glassware. Awareness about the importance of protecting light-sensitive substances is crucial for maintaining the integrity of scientific experiments.

By integrating these practices, laboratories can fully leverage the benefits of amber glassware, ensuring that sensitive solutions are stored and handled in a way that maintains their stability and effectiveness, thereby upholding the highest standards of scientific research.

International Standards for Amber Laboratory Glassware: Ensuring Quality and Safety

In the realm of scientific research and pharmaceutical manufacturing, adhering to international standards is not just a matter of protocol but a necessity for ensuring safety and reliability. Amber laboratory glassware, a staple in many labs for storing sensitive substances, is no exception. These standards provide a framework for manufacturers and users alike, ensuring that every piece of amber glassware meets the highest criteria for quality and safety.

- ASTM E438 – Standard Specification for Glasses in Laboratory Apparatus: This standard, set by ASTM International, classifies different types of glass used in laboratory apparatus, including amber glass. It specifies the chemical resistance, thermal properties, and durability required of these glasses.

- USP <660> – Containers—Glass: The United States Pharmacopeia (USP) sets standards for glass containers used in pharmaceuticals, including amber glass bottles and vials. This standard ensures that the glassware does not react with the substances it holds, maintaining the integrity and efficacy of pharmaceutical products.

- ISO 4802-2:1988 – Hydrolytic resistance of the interior surfaces of glass containers: This standard relates to the testing of glass containers’ resistance to water, ensuring that amber glassware used in labs does not leach into or react with its contents, especially important for sensitive chemical and biological samples.

- EN ISO 4796-1:2019 – Laboratory glassware – Bottles, Part 1: Screw-neck bottles: This European standard specifies requirements for screw-neck bottles, a common type of amber glassware used in labs, ensuring their suitability for storing various substances, including light-sensitive materials.

Adherence to these international standards is essential for maintaining the integrity and efficacy of scientific research and pharmaceutical applications. It’s not just about compliance; it’s about upholding the highest standards of safety and precision in laboratories worldwide. By following these guidelines, researchers and manufacturers can ensure that their amber glassware provides the necessary protection and reliability for sensitive substances.

The Manufacturing Process and Challenges of Amber Laboratory Glassware

Understanding the intricate manufacturing process of amber laboratory glassware is key to appreciating its role in scientific research. This process not only determines the effectiveness of the glassware in protecting sensitive substances but also its overall quality and durability.

The manufacturing of amber lab glassware begins with the careful selection of raw materials. Silica sand, soda ash, limestone, and various additives, including iron oxide and sulfur, are combined to create the distinctive amber color. This coloration is not merely cosmetic; it plays a critical role in filtering out harmful UV and blue light.

Key Steps in the Manufacturing Process:

- Batching: Raw materials are precisely measured and mixed. The addition of iron oxide and sulfur gives the glass its amber hue.

- Melting: The batch is heated in a furnace at extremely high temperatures, typically around 1700°C, to form a homogenous molten glass.

- Forming: The molten glass is then shaped into desired forms, such as vials, bottles, or flasks, using various methods like blowing, pressing, or molding.

- Annealing: This is a critical step where the glassware is slowly cooled to remove internal stresses. Improper annealing can lead to glassware that is prone to cracking.

- Inspection and Testing: Each item undergoes stringent quality checks for imperfections and is tested to ensure it meets the required standards for chemical resistance and durability.

Challenges in Manufacturing:

- Consistency in Coloration: Achieving the exact amber hue consistently is challenging. The color must effectively block the specific light wavelengths without compromising the glass’s clarity and quality.

- Maintaining Chemical Resistance: The glass must be resistant to chemicals and not react with the substances it stores. Ensuring this while adding colorants to the glass mixture is complex.

- Thermal Stability: The glassware must withstand thermal shocks and high temperatures, especially in laboratory environments. Balancing thermal resistance with light-filtering properties requires precise control during the manufacturing process.

- Quality Control: Each piece of glassware must be free from defects and imperfections. Maintaining high-quality standards throughout the manufacturing process is challenging but essential.

The manufacturing of amber laboratory glassware involves a delicate balance of art and science. It requires precise control of materials, temperatures, and processes to produce glassware that not only meets aesthetic standards but more importantly, fulfills its crucial role in protecting sensitive solutions in scientific research. The challenges in manufacturing are significant, but they are what make this glassware an indispensable tool in laboratories around the world.

Additional Benefits of Amber Glassware

Besides its protective role, Amber glassware offers other advantages. It provides a barrier against gas exchange, minimizing oxidation, which can also degrade sensitive substances. Furthermore, amber glass is durable and reusable, aligning with sustainable laboratory practices.

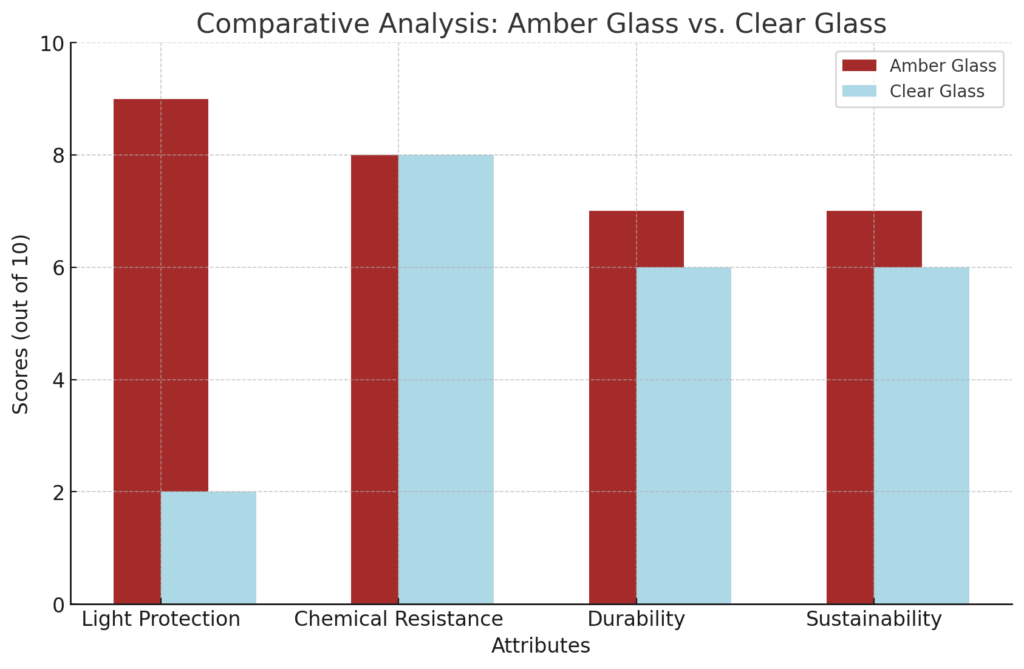

Comparative Analysis: Amber Glass vs. Clear Glass

To enhance the understanding of the advantages of amber glassware compared to other glass materials, let’s create a comparative analysis in the form of a bar chart. This chart will compare key attributes such as light protection, chemical resistance, durability, and sustainability between amber glass and clear glass, which is commonly used in laboratories.

Conclusion

The pivotal role of amber lab glassware in safeguarding sensitive solutions is a testament to the intricate interplay of science and practical application. It stands not just as a tool, but as a guardian in laboratories, protecting the integrity of essential research materials from the subtle yet potent effects of light exposure. For scientists, researchers, and students alike, recognizing and harnessing the protective power of amber glassware is crucial in the pursuit of scientific discovery and innovation. Let us continue to value and incorporate this indispensable ally in our quest for knowledge and progress in the vast world of scientific exploration.