Have you ever wondered how laboratory glassware withstands extreme temperatures without cracking or deforming? What makes certain glassware ideal for high-temperature experiments, while others are not? This curiosity leads us to the world of thermal expansion coefficients, a critical aspect of lab glassware that can either make or break an experiment.

The thermal expansion coefficient is a measure of how much a material expands or contracts when the temperature changes. For lab glassware, understanding and managing this property is crucial for ensuring precision and safety in experiments. It’s not just about the glassware surviving the heat; it’s about maintaining the integrity of the scientific process.

Let’s delve into this fascinating topic and discover the intricate balance between chemistry, physics, and engineering in laboratory glassware.

What is the Thermal Expansion Coefficient of Glassware?

The thermal expansion coefficient is the rate of change in size (length, volume, or area) relative to temperature change in glassware. It’s an essential parameter for evaluating the thermal expansion properties of glassware, influencing both design and engineering applications, as well as material research.

Different types of glass have varying thermal expansion coefficients. For instance, borosilicate glass, commonly used in labs, has a lower coefficient, making it less susceptible to temperature-induced changes. On the other hand, lead glass expands more with heat. These differences are crucial in applications like optical instrument manufacturing, where precision is paramount, and in construction, for designing windows and doors that can withstand temperature variations without damage.

Moreover, the thermal expansion coefficient can also infer the chemical composition and other properties of the glass. By comparing the coefficients of different glasses, one can deduce the presence of elements like lead. This information is valuable for understanding the production techniques and manufacturing methods of the glass.

In essence, the thermal expansion coefficient of glassware is a vital parameter for both research and practical applications. Understanding and mastering it is an indispensable part of design and engineering in these fields.

How Thermal Expansion Affects Laboratory Experiments

Understanding how thermal expansion affects laboratory experiments is crucial for anyone involved in scientific research. This aspect of physical science has profound implications on the reliability, accuracy, and safety of experiments conducted in labs.

The Impact on Measurement Accuracy

In laboratory experiments, accuracy is paramount. Glassware, such as volumetric flasks and pipettes, are calibrated based on specific temperatures, typically at room temperature. However, when these glass instruments are exposed to temperatures significantly higher or lower than the calibration temperature, thermal expansion or contraction occurs. This change in volume can lead to inaccuracies in measurements. For instance, a solution measured at a high temperature in a graduated cylinder might appear to be a different volume when it cools down to room temperature. This can significantly impact the results of experiments, especially those requiring precise quantitative analysis.

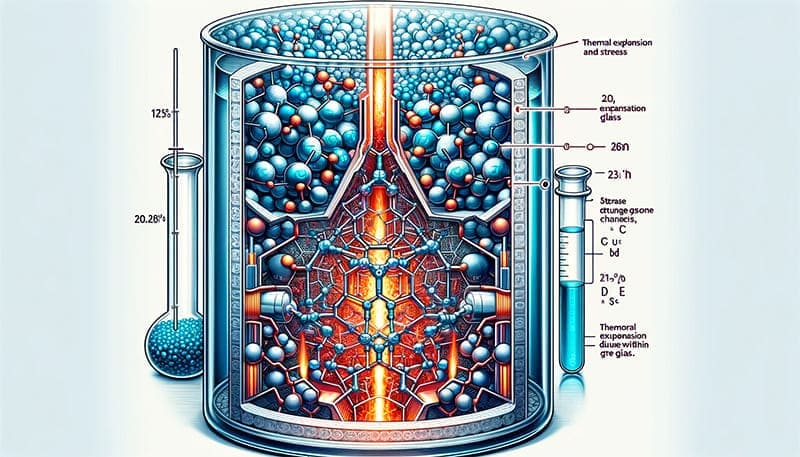

Thermal Shock and Material Integrity

Thermal expansion can also lead to thermal shock, a phenomenon where rapid temperature changes cause stress in the glass material. If the glassware is not designed to withstand such stress (as is the case with non-borosilicate glass), it can crack or shatter. This not only disrupts the experiment but also poses a safety hazard in the laboratory. The selection of appropriate glassware, like borosilicate glass which has a low thermal expansion coefficient and high resistance to thermal shock, is critical for experiments involving sudden temperature changes.

Experimental Design Considerations

Researchers designing experiments must account for the thermal expansion properties of the glassware they intend to use. This includes considering the temperature range the glassware will be exposed to and selecting materials accordingly. Failing to do so can result in experimental errors, equipment damage, and even safety risks.

The implications of thermal expansion in laboratory experiments are significant. From influencing measurement accuracy to dictating the choice of materials and shaping experimental designs, thermal expansion plays a critical role in the world of scientific research. Understanding this concept is essential for the success and safety of laboratory experiments, making it a key topic for both seasoned researchers and students alike.

Factors Influencing Thermal Expansion in Laboratory Glassware

Delving deeper into the realm of laboratory science, it becomes evident that several factors influence the thermal expansion of glassware used in labs. Understanding these factors is essential for choosing the right type of glassware for specific experiments and for ensuring the longevity and safety of these crucial tools.

Chemical Composition of the Glass

The most significant factor affecting the thermal expansion of glassware is its chemical composition. Different types of glass have different compositions, which directly influence their thermal expansion coefficients. For example, borosilicate glass, known for its low thermal expansion coefficient, contains boron oxide, which enhances its resistance to temperature changes. In contrast, soda-lime glass, commonly used in household items, has a higher thermal expansion coefficient and is more susceptible to temperature-induced changes.

Manufacturing Process

The way glassware is manufactured also plays a role in its thermal expansion properties. The cooling and annealing processes that the glass undergoes can affect its internal structure and, consequently, its expansion behavior. Glass that is rapidly cooled from a high temperature may have higher internal stresses, leading to a greater propensity for thermal shock.

Glass Thickness and Shape

The physical dimensions and shape of the glassware can influence how it responds to thermal stress. Thicker glass may be more resistant to rapid temperature changes, but it also means that the glass takes longer to reach thermal equilibrium. Similarly, the shape of the glassware, including aspects like surface area and volume, can affect how heat is distributed across the glass, impacting its overall thermal response.

History of Thermal Stress

The history of thermal stress that the glassware has undergone can also impact its thermal expansion properties. Repeated heating and cooling cycles can weaken the glass structure over time, making it more susceptible to cracking or breaking under subsequent thermal stresses. This is why older glassware in labs may need to be handled with extra care or replaced more frequently.

Environmental Conditions

Lastly, the environmental conditions in which the glassware is used can affect its thermal expansion. Humidity, atmospheric pressure, and the presence of chemicals in the lab environment can interact with the glassware, potentially altering its thermal expansion behavior.

Incorporating an understanding of these factors into the selection and maintenance of laboratory glassware is crucial for ensuring accurate experimental results and maintaining a safe working environment in the lab. It’s a testament to the complex interplay of chemistry, physics, and engineering in the practical world of scientific research.

Thermal Expansion Coefficients of Various Laboratory Glass Materials at Different Temperatures

In the world of laboratory science, understanding the thermal expansion coefficients of different glass materials is crucial. This knowledge not only aids in selecting the right glassware for specific temperature conditions but also ensures the accuracy and safety of experiments. Let’s explore how different glass materials used in laboratory settings respond to temperature changes.

Overview of Thermal Expansion Coefficients

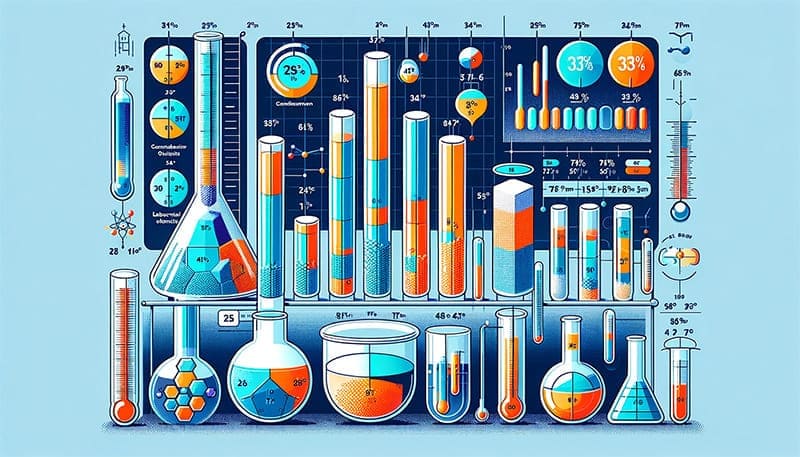

The thermal expansion coefficient is a measure of how much a material expands when the temperature is increased. It is usually expressed in units of per degree Celsius (°C). Different types of glass materials, due to their unique chemical compositions and manufacturing processes, exhibit different thermal expansion behaviors. Here’s a comparative look at some common laboratory glass materials:

Expanded Table of Thermal Expansion Coefficients

| Material Type | Thermal Expansion Coefficient (per °C) | Temperature Range (°C) | Typical Applications | Key Properties |

|---|---|---|---|---|

| Borosilicate Glass | 3.25 x 10^-6 | 20 – 300 | Chemical processing, laboratory use | High thermal resistance, low chemical reactivity |

| Soda-Lime Glass | 8.5 x 10^-6 | 20 – 300 | General purpose, storage containers | Economical, good optical properties, less thermal stability |

| Quartz Glass | 0.54 x 10^-6 | 20 – 300 | High-temperature and UV applications | Excellent thermal stability, high resistance to UV light |

| Pyrex (Type of Borosilicate Glass) | 3.3 x 10^-6 | 20 – 450 | Laboratory glassware, cookware | Very low thermal expansion, high chemical durability |

| Vycor (High-Silica Glass) | 0.55 x 10^-6 | 20 – 350 | Specialized laboratory applications | Extremely high thermal and chemical stability |

Understanding the Expanded Table

This expanded table provides a clearer picture of where each type of glass material excels. For instance, borosilicate glass, with its balance of thermal resistance and chemical stability, is ideal for a wide range of laboratory applications. On the other hand, quartz glass, with its superior thermal stability and resistance to UV light, is well-suited for high-temperature and photonic applications.

Understanding the thermal expansion coefficients of different glass materials is a key aspect of laboratory work. This knowledge helps scientists and lab technicians make informed decisions about which glassware to use in various experimental conditions, ultimately leading to more reliable and safer laboratory practices. As science continues to advance, this understanding becomes ever more critical in the pursuit of precision and safety in scientific research.

How to Measure the Thermal Expansion Coefficient?

Measuring the thermal expansion coefficient of glass instruments is crucial for studying the properties and applications of glass. Here’s a general method to measure the thermal expansion coefficient of glass instruments:

- Prepare Materials and Instruments: Gather a precision electric furnace, a dilatometer (thermal expansion meter), a balance (scale), a thermometer, and a 500 ml glass container.

- Mark the Glass Container: Mark the starting position on the outside of the glass container to measure its change after heating.

- Weigh the Glass Container: Use the balance to weigh the glass container and record its weight.

- Heat the Glass Container: Place the glass container in the precision electric furnace and heat it, while monitoring the temperature with the thermometer. Heat the container to a specific temperature according to the experimental requirements and maintain it for a set duration.

- Measure Thermal Expansion Coefficient: During heating, use the dilatometer to monitor the dimensional changes of the glass container. The thermal expansion coefficient is the rate of length or volume change with temperature and can be calculated using the formula: α = (ΔL/L₀) / ΔT, where α is the thermal expansion coefficient, ΔL is the change in length, L₀ is the initial length, and ΔT is the change in temperature.

- Record Data: Record the weight and dimensional changes of the glass container, along with the corresponding temperatures during the heating process. This data will be used to calculate the thermal expansion coefficient.

- Data Analysis: Calculate the thermal expansion coefficient of the glass container based on the recorded data. Plotting the thermal expansion coefficient against temperature changes can provide a more visual analysis of the properties and applications of the glass.

It’s important to note that measuring the thermal expansion coefficient of glass instruments requires precision equipment and careful operation and data processing. Therefore, adequate preparation and validation of the experimental plan are necessary before conducting the experiment to ensure the accuracy and reliability of the results.

The Intricacies of Thermal Expansion in Lab Glassware

When it comes to laboratory glassware, the devil is in the details. The thermal expansion coefficient not only dictates the choice of glassware for specific experiments but also plays a pivotal role in the longevity and reliability of the equipment. Imagine conducting an experiment that requires gradual heating, and the glassware cracks midway, not only disrupting the experiment but also posing safety risks. This is where understanding and managing the thermal expansion becomes crucial.

The Role of Thermal Expansion in Everyday Lab Scenarios

Every day, lab technicians and scientists face challenges that may seem mundane but are critical. For example, when sterilizing glassware or conducting reactions that involve significant temperature changes, the knowledge of the glassware’s thermal expansion coefficient is indispensable. It helps in selecting the right type of glassware for each experiment, ensuring both safety and accuracy.

The Impact of Thermal Expansion on Precision and Safety

Precision in measurements is the cornerstone of scientific experiments. A slight change in the dimensions of glassware due to thermal expansion can lead to significant errors in experimental results. This is particularly crucial in quantitative chemistry experiments, where precision is paramount. Similarly, the safety aspect cannot be overstated. Glassware that cannot withstand thermal stresses can lead to accidents, contaminating experiments, and causing injuries.

Advanced Glassware: Innovations and Improvements

The ongoing research in material science has led to the development of advanced glassware with tailored thermal expansion properties. Innovations in this field aim to create glass that can withstand higher temperatures with minimal expansion, thereby increasing safety and precision in experiments. These advancements are not just theoretical but have practical applications in industries ranging from pharmaceuticals to aerospace.

Further Questions and Answers

What factors influence the thermal expansion coefficient of glassware?

Chemical composition and glass structure are key determinants. For example, the addition of boron in borosilicate glass reduces its thermal expansion.

How does the thermal expansion coefficient affect the use of glassware in laboratories?

It influences the glassware’s ability to withstand thermal shock. Low coefficients reduce the risk of cracking or breaking when subjected to rapid temperature changes.

Can the thermal expansion coefficient be altered? Yes, by changing the glass’s chemical composition during manufacturing.

How does thermal expansion affect the calibration of glassware?

Calibration can be impacted by thermal expansion. As glass expands or contracts, the volume measurements may no longer be accurate, which is particularly crucial in volumetric glassware like pipettes and burettes.

Is there a universal type of glassware that’s best for all lab conditions?

No, there’s no one-size-fits-all in lab glassware. The choice depends on the specific requirements of the experiment, including the temperature range and chemical reactivity.

New Materials and Technologies Addressing Thermal Expansion Challenges in Laboratory Glassware

As science and technology advance, new materials and innovative techniques are being developed to address the challenges of thermal expansion in laboratory glassware. These advancements are not only enhancing the durability and safety of glassware but also expanding the possibilities for scientific research. Let’s explore some of the latest developments in this field.

Nanocomposite Materials

Researchers are experimenting with nanocomposite materials to create glassware with improved thermal properties. These nanocomposites involve embedding nanoparticles into traditional glass matrices, which can significantly alter the thermal expansion characteristics. For example, adding silica nanoparticles to borosilicate glass can enhance its thermal stability and resistance to thermal shock.

Reinforced Glassware

Another approach is the reinforcement of glassware with heat-resistant coatings. These coatings are typically made from materials like silicon carbide or titanium dioxide, which not only reduce the thermal expansion coefficient but also increase the mechanical strength of the glass. This makes the glassware more resilient to sudden temperature changes and reduces the risk of breakage.

Smart Glass Technologies

Smart glass technologies, which involve the use of responsive materials, are being explored for lab glassware. These materials can change their properties in response to temperature fluctuations, thereby reducing the impact of thermal expansion. For instance, glassware coated with thermochromic materials can indicate temperature changes, alerting lab personnel to potential thermal stress issues.

Advanced Manufacturing Techniques

Improvements in glass manufacturing techniques are also playing a crucial role. Controlled cooling and annealing processes are being refined to reduce internal stresses and improve the uniformity of the glass structure. Advanced 3D printing technologies are also being explored to manufacture glassware with precise thermal properties, tailored to specific experimental needs.

Eco-friendly Glass Alternatives

There is also a growing interest in developing eco-friendly alternatives to traditional glass materials. Researchers are focusing on bio-based and recyclable materials that can withstand high temperatures with minimal expansion. These sustainable options not only address thermal expansion issues but also contribute to environmental conservation.

These innovations in materials and technologies are revolutionizing the field of laboratory glassware. By addressing the challenges of thermal expansion, they are not only enhancing the safety and reliability of glassware but also paving the way for more advanced and diverse scientific experiments. As research continues, we can expect to see further groundbreaking developments that will continue to transform the landscape of laboratory science.

Final Thoughts on Navigating Thermal Expansion in Lab Glassware

In the realm of laboratory science, understanding the nuances of materials, especially something as foundational as glassware, is vital. The thermal expansion coefficient is more than just a scientific term; it’s a critical factor that influences the outcome of experiments and the safety of laboratory environments. This is a testament to the importance of interdisciplinary knowledge in science, where physics, chemistry, and engineering converge to facilitate groundbreaking research and ensure safety in laboratories.

And there you have it, an in-depth look at the hot topic of lab glassware and navigating thermal expansion coefficients. Remember, in the lab, every detail counts, especially when it comes to the materials we rely on for scientific discovery.

Conclusion

Navigating the complexities of thermal expansion in lab glassware is not just a scientific endeavor but a call to action for meticulousness and innovation in laboratory practices. Understanding the thermal expansion coefficient is imperative for precision, safety, and success in scientific research. Let’s embrace this knowledge, continually seek improvements in materials science, and apply this understanding rigorously to advance the frontiers of scientific discovery. Together, we can ensure safer, more reliable, and groundbreaking experiments in laboratories worldwide.