Have you ever wondered why certain laboratory glassware feels heavier than others? Or why the density of these glass tools is crucial for scientific experiments? These questions might seem trivial, but they open a window into the fascinating world of laboratory science.

Laboratory glassware is more than just containers; they are critical tools in scientific research. The density of glassware determines its weight, stability, and chemical resistance, making it a vital factor in the world of science. Knowing about the density of glassware can enhance the precision and safety of experiments.

Now, let’s explore this topic in depth and unravel the mystery behind the density of laboratory glassware.

What is Laboratory Glassware Density?

The density of laboratory glassware refers to its mass per unit volume. This property varies among different types of glassware and is a critical factor in their functionality.

Laboratory glassware, typically made from borosilicate glass, is renowned for its high temperature resistance, corrosion resistance, and chemical stability. These properties are influenced by the glassware’s density.

In scientific terms, density is often represented as specific gravity or relative density. For laboratory glassware, these terms mean different things. Specific gravity is the density of the glass at 20℃ compared to the density of water at 4℃. Relative density, on the other hand, is the ratio of the density of the glass to the density of an equal volume of water.

Understanding the density of laboratory glassware is essential for ensuring the accuracy and safety of experiments.

The Importance of Glassware Density in Laboratories

The density of glassware affects its performance and safety in the lab. Denser glassware tends to be heavier, more durable, and chemically stable. Choosing glassware with the appropriate density is crucial for ensuring the accuracy and safety of experiments.

How Glassware Density Affects Experiments

- Even Heating and Cooling: Glassware with higher density is like a thick-bottomed cooking pot. It heats and cools down more evenly. This is important in experiments where you need to heat chemicals. Uneven heating can lead to unexpected results, just like how unevenly heated food can cook poorly.

- Not Reacting with Chemicals: Some experiments are like baking a cake – you don’t want your pan affecting the taste. In labs, if the glassware reacts with the chemicals inside, it can change the experiment’s outcome. Higher density glassware is less likely to react with the chemicals, keeping the experiment “taste” pure.

- Holding Shape Over Time: Just like good quality kitchenware, high-density lab glassware doesn’t warp or change shape easily. This is crucial for experiments where measuring exact amounts is important. Imagine trying to measure a cup of flour in a bent cup; your measurements would be off.

Why Glassware Density is Key for Safety

- Less Likely to Break: Thicker, denser glassware is stronger. In a lab, using stronger glassware is safer, especially when dealing with dangerous chemicals. It’s like using a sturdy glass jar instead of a thin one that can easily crack.

- Handles Temperature Changes Better: High-density glassware can handle quick temperature changes without cracking. It’s like using a dish in the oven that doesn’t crack when you take it out. In a lab, this means fewer accidents with glass breaking due to sudden heat.

- Prevents Leaks and Spills: Strong, dense glassware is less likely to leak or break under pressure, much like a good quality water bottle. This is important for keeping both the experiments and the scientists safe from spills and exposure to harmful chemicals.

In simple terms, the density of lab glassware is all about choosing the right “tools” for the job. Just like in cooking, using the right type of glassware ensures that experiments run smoothly and safely, much like how the right pot or pan ensures your meal turns out just right.

Understanding Changes in Glassware Density During Experiments

In a laboratory, glassware is like a dance partner in the world of science; it needs to move and adjust with the experiment. However, just like a dance floor can affect a dancer’s performance, the conditions in an experiment can affect the glassware’s density. Here’s how:

How Density Changes

- Temperature Effects: Imagine a chocolate bar melting in the sun. Similarly, when glassware is heated, its material expands slightly. This expansion can slightly decrease the glassware’s density. Conversely, when it cools down, it contracts, and its density returns to normal. This is like the chocolate bar solidifying again in the fridge.

- Chemical Reactions: Sometimes, glassware can react with chemicals in an experiment. It’s like dipping a metal spoon in a corrosive liquid, which might make it rust or change. If the glassware’s surface reacts, it might become slightly more porous (have tiny holes), affecting its density.

What to Pay Attention to

- Avoid Extreme Temperature Changes: Just like you wouldn’t put a hot glass dish into cold water (because it might crack), avoid sudden temperature changes with laboratory glassware. Gradual changes are safer and help maintain the glassware’s integrity.

- Choose the Right Glass for the Right Chemical: Just as you wouldn’t store tomato sauce in a metal container (because it can react and taste metallic), use glassware that’s suitable for the chemicals in your experiment. Some glass is made to resist certain chemicals and won’t change as much.

- Regular Checks for Wear and Tear: Just like checking your car tires for wear, regularly inspect your glassware. Look for signs of etching, cloudiness, or cracks. These can indicate changes in the glassware that might affect your experiment.

- Be Mindful of Cleaning Methods: Cleaning glassware is like washing dishes; you need the right soap and water temperature. Harsh chemicals or improper cleaning can wear down glassware over time, changing its density.

In a nutshell, laboratory glassware, much like any tool, undergoes changes and needs proper care. By understanding how these changes occur and what to watch out for, scientists can ensure their experiments are as accurate and safe as possible. It’s all about knowing your tools and how to take care of them, ensuring they perform at their best in the scientific dance of discovery.

Comparing Densities of Various Laboratory Glassware Materials

When we talk about laboratory glassware, it’s not just glass in the traditional sense. Laboratories use a range of materials, each with its unique properties and densities. Understanding these differences is like knowing why a chef chooses a cast iron skillet over a non-stick pan for certain recipes. Here’s a look at some common materials used for laboratory glassware and their respective densities.

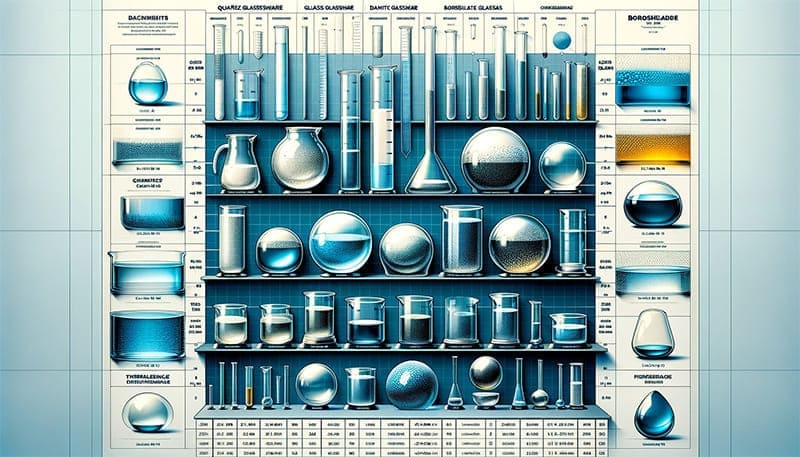

The Table of Densities and Properties of Different Glassware Materials

| Material | Density (g/cm³) | Key Properties | Typical Uses | Thermal Resistance |

|---|---|---|---|---|

| Borosilicate Glass | 2.23 | Resistant to thermal shock, low expansion | General lab use, high-temperature applications | Excellent |

| Soda-Lime Glass | 2.50 | Inexpensive, less resistant to chemicals and heat | Storage containers, simple lab tasks | Moderate |

| Quartz Glass | 2.20 | Excellent thermal properties, high chemical purity | UV applications, precise optical work | Very High |

| Lead Glass | 3.10 – 5.90 | High refractive index, used for optical components | Optical lenses, radiation shielding | Low to Moderate |

| Alumina-Silicate Glass | 2.6 | Resistant to high temperatures and thermal shock | Furnace tubes, high-temperature applications | Very High |

| Polyethylene (Plastic) | 0.95 – 0.96 | Lightweight, chemical resistant, less durable | Non-reactive storage, disposable containers | Low |

| Polytetrafluoroethylene (PTFE, Teflon) | 2.2 | Chemical resistant, used in non-stick coatings | Corrosive material handling, non-stick surfaces | Moderate to High |

Elaborating on the Table

This expanded table provides a more comprehensive view of the various materials used in laboratory glassware. For instance, while borosilicate glass is ideal for high-temperature work due to its excellent thermal resistance, soda-lime glass is more suited for general storage and simple tasks due to its moderate thermal resistance and lower cost.

The choice of material for laboratory glassware goes beyond just considering density; it also involves understanding each material’s suitability for different types of laboratory work. This knowledge is crucial for ensuring the safety, accuracy, and efficiency of scientific experiments. It’s the kind of practical science that empowers researchers to conduct their work effectively.

Measuring the Density of Laboratory Glassware

Measuring the density of glassware is crucial for quality control and laboratory safety. Here are the methods to measure the density of glassware:

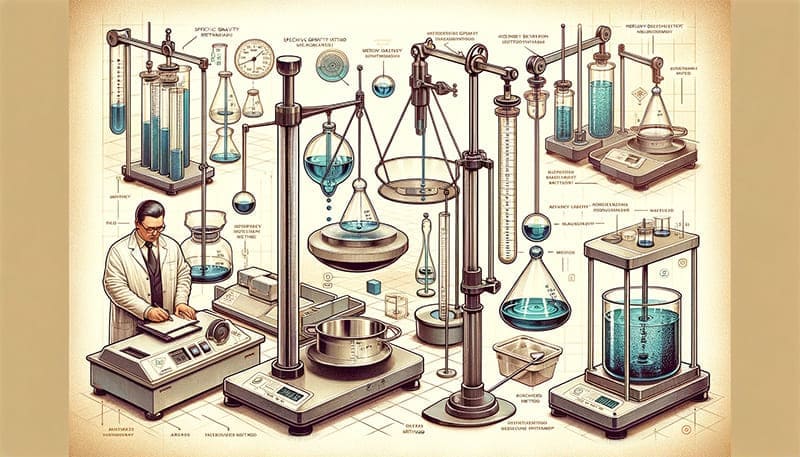

Specific Gravity Method

This method compares the density of glass to that of water. The steps are as follows:

- Select a Container: Choose an accurate mass-measuring container, like a conical or round-bottom flask.

- Prepare the Sample: Weigh a certain mass of the sample, clean it thoroughly with water, and place it in the container.

- Add Water: Pour a specific amount of water into the container and submerge it in room temperature water, adjusting its position to ensure full immersion.

- Measure Liquid Level: Read the liquid level displaced by the glass sample and calculate the glass density using a fixed formula.

This method can be limited by environmental conditions and may have significant errors. However, it remains an option when professional instruments are unavailable.

Mercury Displacement Method

This is a convenient method to measure glass density. The steps are as follows:

- Prepare Mercury-Filled Device: Fill a device with known-density mercury and fix it, ensuring no bubbles adhere to the sample’s surface.

- Stable Environment: Place the device in a sealed container in a constant temperature environment.

- Add Water: Add a known volume of pure water to reach a certain level in the device.

- Place Sample: Insert the sample into the device, causing the water level to rise. The difference in levels indicates the volume occupied by the sample.

- Calculate Density: When mercury is drawn from the bottom of the device, the glass sample volume appears equal. The sample’s density can then be calculated using a simple formula.

This method is relatively simple, not affected by environmental conditions, and applicable to various shapes and sizes of glass samples. However, due to the use of mercury, safety and environmental considerations are important.

Buoyancy Method (Archimedes’ Principle)

This method also measures the glass density by comparing it with water’s density. The steps are:

- Use Analytical Balance: Use an accurate electronic balance to measure a 20g sample. Choose a sample free of bubbles, inclusions, or impurities. If cut into a cylinder or rectangle, ensure smooth surfaces and slightly rounded edges without cracks. Weigh the glass sample in air, noted as Ma.

- Submerge Sample: Place the sample in a basket or ring holder, suspend it in water using a suitable hook and suspension wire, and weigh the submerged glass sample and suspension assembly together, noted as Mt. Remove the glass sample from the holder and weigh the empty suspension assembly in water. Note the densities of air (ρa) and distilled water (ρw).

- Calculate Density: Use the formula ρ={Maρw-(Mt-Mw)}/(Ma-Mt-M0) to calculate the glass density.

Each of these methods has its advantages and limitations, and the choice of method depends on the specific requirements of the experiment or quality control process.

The Quality Implications of Glassware Density in Laboratories

When it comes to laboratory glassware, the density isn’t just about how heavy or light the material is; it’s also a marker of quality. Understanding this aspect is akin to knowing why chefs prefer certain pans for specific dishes based on their quality. Here’s how the density of glassware in a lab correlates with its quality and why it matters.

Density as an Indicator of Glassware Quality

- Durability and Longevity: Higher density in laboratory glassware typically implies a more durable and long-lasting material. Dense glassware can withstand repeated use and cleaning without showing signs of wear as quickly as less dense alternatives. This durability is akin to using a well-crafted cooking pot that lasts for years, providing consistency in cooking results.

- Resistance to Chemicals and Heat: The density of glassware can indicate its resistance to chemicals and heat. Denser glassware generally has a tighter molecular structure, making it less prone to chemical attacks and able to withstand higher temperatures without degrading. This characteristic is crucial in experiments that involve corrosive substances or require heating, much like using a heavy-duty pan for high-heat cooking.

- Precision in Experiments: The quality of laboratory glassware, as reflected in its density, affects the precision of measurements and experiments. Higher density glassware maintains its shape and calibration over time, ensuring accurate measurements. This precision is vital in experiments where even minor discrepancies can lead to significant errors in results, similar to the importance of precise measurements in baking.

The density of laboratory glassware is a critical factor in determining its quality. Just as a chef chooses kitchenware based on quality for the best cooking results, scientists must select glassware based on density to ensure the success and safety of their experiments. Understanding this connection between density and quality is key to maintaining high standards in scientific research.

The Economic Perspective on Glassware Density in Laboratories

When considering laboratory glassware, the density isn’t just a scientific concern; it also has significant economic implications. Like choosing between a budget-friendly cooking pan and a high-end one, the choice of glassware in a laboratory often involves balancing cost and quality. Here’s a closer look at how the density of glassware affects its economic aspects.

Cost Implications of Glassware Density

- Initial Investment vs. Longevity: Denser, high-quality glassware typically comes with a higher price tag. However, this initial investment can be economical in the long run. Denser glassware often lasts longer and withstands rigorous use, reducing the need for frequent replacements. This is similar to investing in a good quality kitchen appliance that might be expensive upfront but saves money over time.

- Maintenance and Replacement Costs: The density of glassware influences its durability and resistance to wear. Lower density glassware, while cheaper, may need to be replaced more often, especially if used under harsh conditions. This can lead to higher maintenance and replacement costs, akin to frequently replacing cheap kitchenware that wears out quickly.

- Efficiency and Accuracy: High-density glassware tends to provide more accurate and consistent results in experiments. This efficiency can lead to cost savings by reducing the need for repeat experiments and wasted materials. It’s like using a reliable oven that cooks food evenly, avoiding waste and extra energy costs.

The density of laboratory glassware is an important economic consideration. It affects not just the initial purchase price, but also long-term costs related to durability, maintenance, and experiment efficiency. Understanding these economic implications helps laboratories make informed decisions that balance quality with cost, ensuring the best use of their resources.

Balancing Cost and Quality: The Economic Aspect of Glassware Density

In the realm of scientific research, budget constraints are a common challenge. The density of laboratory glassware also plays a significant role in its cost. Higher-density glassware, while offering greater durability and chemical resistance, often comes at a higher price. This creates a delicate balance for laboratories to strike between cost-efficiency and maintaining high standards of quality and safety.

Institutions often have to weigh the long-term benefits of investing in higher-density, more expensive glassware against immediate budget limitations. The decision impacts not just the quality of research but also long-term financial sustainability. Investing in quality glassware can reduce the need for frequent replacements, ultimately proving cost-effective in the long run.

Conclusion

The density of laboratory glassware is more than a mere physical attribute; it’s a cornerstone of precision, safety, and efficiency in scientific research. As we’ve journeyed through the varied facets of this topic, it’s clear that understanding and applying this knowledge is pivotal in advancing the frontiers of science. Let’s embrace this deeper insight into the tools of our trade and continue to push the boundaries of discovery. Remember, every choice in the lab, no matter how small, shapes the path of scientific progress. Embrace the heavier side of science, and let’s innovate with wisdom and foresight.