Have you ever wondered why your kitchen experiments or science projects don’t turn out as expected? Could it be something as simple as the way you measure liquids? Misreading measurements can lead to disastrous outcomes in both cooking and scientific experiments.

Understanding the nuances of using graduated cylinders and measuring cups is key to precision and accuracy. These tools are more than just containers with markings; they are instruments of accuracy that can make or break your outcomes. Let’s dive into how to use them correctly to ensure you get the most accurate measurements.

Precision in the Palm of Your Hand: Why Accuracy Matters

Graduated cylinders and measuring cups are staples in both laboratories and kitchens. They’re designed for accuracy with clear markings and are typically made from glass or plastic for durability and stability. But why is precision so important? In cooking, the right amount of an ingredient can affect flavor and texture. In a lab, precision is critical for valid results.

Navigating the Diversity of Graduated Cylinders and Measuring Cups

Selecting the right tool for measuring liquids is crucial for accuracy in both scientific experiments and culinary preparations. Different types of graduated cylinders and measuring cups cater to various needs, offering unique features and applications. Below is a detailed breakdown of some common types and their specific attributes.

| Type | Material | Features | Applications | Considerations |

|---|---|---|---|---|

| Graduated Cylinder, Round Base | Glass/Plastic | Stable with a round base, precise markings | General laboratory use | Glass is fragile, plastic may react with chemicals |

| Graduated Cylinder, Hexagon Base | Glass/Plastic | Hexagonal base for extra stability, clear markings | Laboratories where stability is key | Same as round base; hexagon base adds more stability |

| Conical Measuring Cylinder Cup | Plastic | Conical shape, easy pouring, visible measurements | Cooking, casual laboratory use | Not as precise as straight-walled cylinders |

| Measuring Cylinder with Stopper | Glass/Plastic | Includes a stopper for storing liquids, precise measurements | Storing and measuring reactive liquids | Be cautious with reactive liquids; handle with care |

Understanding the characteristics and best uses of each type can significantly aid in choosing the right cylinder or cup for your specific requirements. Whether for a high-precision lab experiment or for culinary precision, the right choice can make a significant difference in the outcome.

The Importance of Calibration in Graduated Cylinders and Measuring Cups

Calibration is a critical aspect when it comes to achieving precise measurements with graduated cylinders and measuring cups. Over time, these instruments can lose their accuracy due to wear and tear, chemical exposure, or physical damage. Regular calibration ensures that they provide accurate readings, which is especially crucial in professional laboratories and for culinary experts who rely on precision.

Understanding Calibration

Calibration involves comparing the measurements of your instrument with a standard or known measurement. For graduated cylinders and measuring cups, this usually means verifying that the

volume markings correspond accurately to the actual volume of liquid they hold. This process can identify any discrepancies between the marked and actual volumes, allowing for adjustments or the replacement of inaccurate equipment.

How to Calibrate Graduated Cylinders and Measuring Cups

- Select a Standard Liquid: Typically, water is used due to its easily definable density and non-reactive nature.

- Measure at a Controlled Temperature: Since liquid volumes can change with temperature, perform calibration at a consistent, known temperature.

- Use a Precise Instrument: A high-precision instrument, like a volumetric flask, is used as a reference to measure the liquid.

- Fill and Compare: Fill the graduated cylinder or measuring cup with the liquid, then pour it into the volumetric flask to compare the volume.

- Record Discrepancies: Note any differences between the expected and actual measurements. This step is crucial for determining the accuracy of your measuring tools.

- Repeat for Accuracy: Conduct the calibration several times to ensure consistency in your findings.

When to Calibrate

- Regular Intervals: Establish a routine calibration schedule, especially for equipment used frequently or for critical measurements.

- After Repair or Damage: Calibrate immediately if your cylinder or cup has been repaired, dropped, or otherwise potentially compromised.

- Change of Use: If you’re starting to use the equipment for a new type of liquid or a different measurement range, recalibrate to ensure accuracy.

Regular calibration of graduated cylinders and measuring cups is essential for maintaining their accuracy. This process not only ensures the reliability of your measurements but also contributes to the longevity of your equipment. Whether in a lab or a kitchen, the accuracy of your tools is paramount to the success of your work.

A Step-by-Step Guide to Using Graduated Cylinders and Cups Correctly

Measuring cylinders and measuring cups are commonly used instruments in laboratories and everyday life for measuring the volume of liquids. They are characterized by accurate scale markings, high transparency, and are typically made of glass or plastic, which provides excellent durability and stability. Here’s how to correctly use measuring cylinders and cups, along with some important considerations:

Preparation Stage

Before using a measuring cylinder or cup, check that the scale is clear and accurate, and ensure there are no damages or cracks. Also, choose a suitable container to place the cylinder or cup to avoid contamination or loss during measurement.

Operation Stage

- Pouring Liquid: When pouring liquid into the cylinder or cup, control the flow rate to avoid it being too fast or slow. Place the cylinder or cup on a surface, tilt your container, and pour the liquid slowly to prevent splashing or foaming.

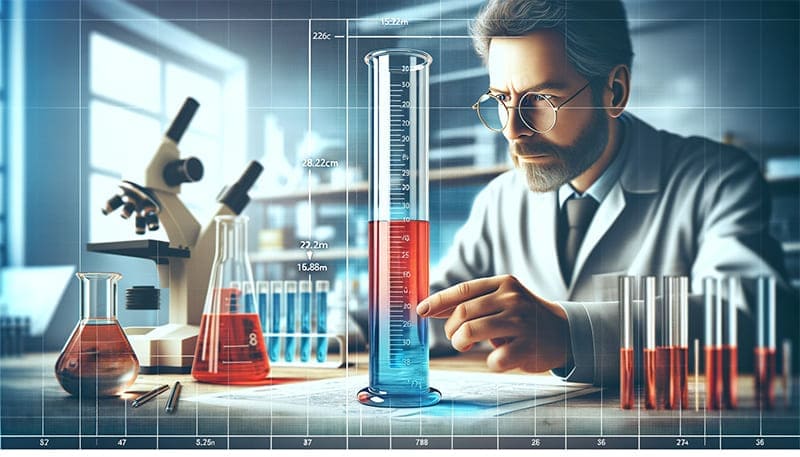

- Reading the Scale: Keep your line of sight level with the liquid’s surface to avoid inaccurate readings due to looking down or up. If the liquid forms a concave or convex surface, use the lowest or highest point of the liquid level for reading.

- Cleanliness During Measurement: Keep the cylinder or cup clean to avoid residue or dirt affecting the measurement accuracy. If measuring multiple samples consecutively, clean and dry the cylinder or cup after each use before the next measurement.

Completion Stage

After measurement, promptly clean the cylinder or cup to remove any residues or dirt. Use appropriate cleaning agents and water, and dry with a clean cloth. Check for damages or cracks, and store properly for future use.

Safety Considerations

- Be cautious to avoid cuts and breakages, especially when cleaning.

- If using electric heating devices, check for damaged or aged power cords to prevent electric shocks or fire hazards.

- Avoid using measuring cylinders or cups in high-temperature environments to prevent deformation or damage.

- When measuring toxic or corrosive liquids, wear protective clothing and gloves, and ensure airtight connections to prevent leaks.

- Clean up the area after experiments, disposing of hazardous waste according to regulations.

- Avoid strong vibrations or impacts on the cylinders or cups to maintain accuracy and lifespan.

- Do not expose them to direct sunlight or high temperatures, which could cause scale inaccuracies or deformation.

General Tips

- Understand the usage methods and precautions of measuring cylinders and cups and follow them strictly.

- Stop using and check or repair them immediately if any abnormalities are detected.

- Choose the appropriate size and type of cylinder or cup to meet experimental needs and pay attention to their material and manufacturing quality.

In summary, correctly using measuring cylinders and cups is an essential skill in the laboratory and everyday life. Mastering their usage, maintenance, and safety precautions can greatly improve experimental efficiency and accuracy, as well as extend the lifespan of these instruments.

Enhancing Accuracy: Tips for Precise Liquid Measurement

Using graduated cylinders and measuring cups correctly can drastically improve the precision of your measurements. Here are some expert tips to ensure you’re measuring liquids accurately:

- Pour Slowly and Steadily: Pouring too fast can create bubbles or spillage, leading to inaccurate measurements. Slow and steady wins the race here.

- Eye Level Is Key: When reading measurements, ensure your eyes are level with the marking. This avoids parallax errors, a common mistake where readings vary based on the angle of viewing.

- Consider Temperature: Remember, liquids expand or contract with temperature changes. Measure liquids at a consistent temperature for accurate results, especially crucial in scientific experiments.

Cleaning and Maintenance: Ensuring Longevity and Precision

Proper cleaning and maintenance of your graduated cylinders and measuring cups are crucial. Here’s how to keep them in top condition:

- Rinse After Use: Always rinse these instruments immediately after use. This prevents residue build-up, which can affect future measurements.

- Use Appropriate Cleaners: Avoid harsh chemicals that can damage the material. Mild soap and water are usually sufficient.

- Dry Thoroughly: Before storing, ensure they are completely dry to avoid mold or water spots that can obscure readings.

Avoiding Common Mistakes

Even experienced users can make mistakes. Be aware of these common pitfalls:

- Ignoring the Meniscus: Always read from the lowest point of the meniscus for concave surfaces and the highest point for convex surfaces.

- Using Damaged Equipment: Cracks or chips can affect the accuracy. Inspect your equipment regularly.

- Inconsistent Reading Angles: Always read from a straight, eye-level angle.

Advanced Techniques: Beyond the Basics

For those seeking even greater precision:

- Use a Pipette for Smaller Volumes: When dealing with very small volumes, a pipette can offer more precision than a graduated cylinder.

- Calibration: Regular calibration of your measuring instruments can ensure ongoing accuracy, especially in a professional lab setting.

Handling Emergencies and Contingency Planning

In the use of graduated cylinders and measuring cups, unexpected situations can arise, ranging from minor spills to more serious accidents. Having contingency plans and knowing how to respond to these situations is crucial for maintaining safety and minimizing potential harm or damage.

Common Emergencies and Responses

- Breakage and Spills:

- Immediate Action: If a cylinder or cup breaks, causing a spill, prioritize personal safety. Wear protective gear if the spilled substance is hazardous.

- Containment: Contain the spill to prevent it from spreading. Use absorbent materials for liquid spills.

- Clean-Up: Clean the spill according to the nature of the liquid. For hazardous materials, follow specific disposal protocols.

- Chemical Reactions:

- Observation: Be alert for unexpected reactions when mixing chemicals, such as excessive heat, fumes, or color changes.

- Containment and Ventilation: If a reaction becomes volatile, contain it if safely possible and ensure adequate ventilation.

- Evacuation: In severe cases, evacuate the area and alert emergency services.

- Injury from Broken Glass or Sharp Edges:

- First Aid: Treat any cuts with immediate first aid. Seek medical attention for serious injuries.

- Disposal of Broken Glass: Dispose of broken glassware in designated containers, not regular trash bins.

Contingency Planning

- Emergency Protocols: Establish clear emergency protocols for different types of accidents. Ensure that all users are familiar with these procedures.

- Personal Protective Equipment (PPE): Always have appropriate PPE available, such as gloves, goggles, and lab coats.

- Regular Training: Conduct regular training sessions on emergency response and safe handling practices.

- Safety Equipment: Equip the laboratory or workspace with safety equipment, including fire extinguishers, eye wash stations, and first aid kits.

- Maintenance Checks: Regularly check equipment for any signs of wear, damage, or malfunction.

Documentation and Reporting

- Incident Logs: Maintain logs of all incidents, however minor. This helps in understanding risks and improving safety measures.

- Regulatory Reporting: Report significant incidents to relevant authorities as required by law or organizational policies.

Preparation and awareness are key to effectively handling emergencies involving graduated cylinders and measuring cups. By implementing comprehensive contingency plans and ensuring regular safety training, the risks associated with these incidents can be significantly mitigated. Remember, safety is always the top priority in any laboratory or kitchen setting.

Selecting the Right Instrument for Specific Tasks

Choosing the appropriate graduated cylinder or measuring cup for a particular task is essential for achieving the best results. Whether in a laboratory setting or in everyday kitchen use, the selection depends on various factors including the nature of the liquid, the volume needed, and the required precision.

Guidelines for Selection

- Volume Requirements:

- Small Volumes (up to 100 ml): For small volumes, a graduated cylinder with a narrow diameter offers more precision.

- Large Volumes: For larger volumes, consider using a measuring cup or a larger graduated cylinder.

- Material Considerations:

- Glass: Best for laboratory use where chemical resistance and heat tolerance are needed. Ideal for volatile organic compounds or corrosive liquids.

- Plastic: Suitable for educational purposes or environments where breakage is a concern. Not recommended for long-term storage of solvents or corrosive liquids.

- Metal: Primarily used in kitchens for handling hot liquids. Not suitable for use with acidic substances.

- Type of Base:

- Round Base: Standard and stable, suitable for most tasks.

- Hexagon Base: Offers additional stability, ideal for environments where knocking over cylinders could be disastrous.

- Special Features:

- Conical Measuring Cups: These are more suitable for kitchen use where precise measurements are not as critical but easy pouring is beneficial.

- Cylinders with Stoppers: Ideal for storing reactive liquids or for experiments that require the mixture to be sealed.

Application-Specific Recommendations

- Laboratory Experiments: Opt for glass graduated cylinders for their accuracy and chemical resistance. The size should be chosen based on the volume of liquid typically measured.

- Cooking and Baking: Metal or plastic measuring cups are more practical. For recipes requiring precise liquid measurements, glass measuring cups with clear markings are preferable.

- Educational Settings: Plastic graduated cylinders are safer and more durable for use in classrooms.

Final Considerations

Before finalizing your choice, consider the environment in which the instrument will be used, the types of liquids you’ll be measuring, and the level of precision required. Each material and design has its advantages and limitations, and the right choice depends on balancing these factors against the needs of your specific task.

Legal and Standardization Aspects

The manufacturing and usage of graduated cylinders and measuring cups, especially in professional settings, are governed by various legal standards and regulations. These standards ensure that measurements are accurate, reliable, and consistent across different industries and applications. Understanding these legal and standardization aspects is crucial for professionals who rely on precise measurements in their work.

International Standards

- ISO Standards: The International Organization for Standardization (ISO) sets global standards for many products, including graduated cylinders and measuring cups. These standards cover aspects like material quality, calibration, and markings.

- ASTM Standards: The American Society for Testing and Materials (ASTM) provides guidelines for the design, material, and performance of laboratory glassware, including graduated cylinders.

Industry-Specific Guidelines

- Pharmaceuticals and Healthcare: In these industries, equipment must comply with stringent regulations for accuracy and cleanliness. This often requires regular calibration and certification of measuring instruments.

- Food and Beverage Industry: Measuring instruments must meet food safety standards, such as being made from food-grade materials and being easy to clean to prevent contamination.

Compliance and Certification

- CE Marking: In Europe, measuring instruments must often bear the CE mark, indicating compliance with EU safety, health, and environmental requirements.

- Calibration Certificates: Professional laboratories may require graduated cylinders and measuring cups to come with calibration certificates, ensuring they meet specific accuracy standards.

Legal Implications

- Mislabeling and Inaccuracy: There can be legal consequences for selling or using measuring instruments that are inaccurately labeled or do not meet the declared specifications.

- Health and Safety Regulations: Non-compliance with health and safety standards, particularly in industries like pharmaceuticals and food, can lead to legal penalties.

Best Practices for Compliance

- Regular Calibration and Verification: Ensure that measuring instruments are regularly calibrated and verified against standard measurements.

- Purchase from Reputable Suppliers: Buy equipment from reputable manufacturers that adhere to international and industry-specific standards.

- Stay Informed: Keep updated with changes in regulations and standards, as they can evolve over time.

Compliance with legal standards and regulations is essential for the manufacturing and usage of graduated cylinders and measuring cups in professional settings. Adherence to these standards ensures not only the accuracy and reliability of measurements but also the safety and effectiveness of the operations in which they are used.

Environmental Considerations and Sustainability

In the context of graduated cylinders and measuring cups, environmental sustainability is an important aspect to consider. The manufacturing and disposal of these instruments, particularly those made of plastic, can have significant environmental impacts. It’s crucial to be aware of these issues and explore eco-friendly alternatives and practices.

Manufacturing and Disposal Concerns

- Plastic Instruments: The production of plastic graduated cylinders and cups involves the consumption of fossil fuels and the emission of greenhouse gases. Additionally, plastic waste can contribute to environmental pollution, particularly if not disposed of properly.

- Glass and Metal Instruments: While these materials are more sustainable than plastic, their production still consumes energy and resources. However, they are more durable and can be recycled more effectively.

Eco-Friendly Alternatives

- Biodegradable Plastics: Some manufacturers are now producing biodegradable plastic cylinders and cups, which decompose more quickly and have a lesser environmental impact.

- Recycled Materials: Opt for instruments made from recycled materials. This not only reduces waste but also the demand for new raw materials.

- Borosilicate Glass: This type of glass is highly durable and resistant to thermal shock, making it a long-lasting choice that can reduce the need for frequent replacements.

Best Practices for Sustainable Use and Disposal

- Longevity and Maintenance: Choose durable instruments and maintain them well to extend their lifespan. This reduces the need for frequent replacements and, consequently, the environmental footprint.

- Proper Disposal: If a graduated cylinder or measuring cup is no longer usable, dispose of it responsibly. Glass and metal can often be recycled, while plastic should be disposed of in accordance with local recycling guidelines.

- Reduce, Reuse, Recycle: Follow the principles of reducing waste, reusing where possible, and recycling when an item reaches the end of its life.

- Educate and Advocate: Spread awareness about the environmental impacts of these instruments and encourage the adoption of sustainable practices in your workplace or community.

By considering these environmental aspects and adopting sustainable practices, we can significantly reduce the ecological footprint of using graduated cylinders and measuring cups. These efforts contribute to a healthier planet and a more sustainable future.

Frequently Asked Questions (FAQs)

In this section, we address some common questions and misconceptions about using and maintaining graduated cylinders and measuring cups. This information is crucial for ensuring accuracy, longevity, and safety in their use.

Q1: What is the Best Way to Clean Graduated Cylinders and Measuring Cups?

- A: For glass and metal instruments, use mild soap and warm water. Rinse thoroughly to remove any soap residue. For plastic, avoid harsh chemicals which can cause the material to degrade. Always dry them completely before storing to prevent mold or water spots.

Q2: How Often Should I Calibrate My Measuring Instruments?

- A: Calibration frequency depends on usage. For high-precision laboratory work, calibrate before each experiment or at least once a month. In kitchen or educational settings, a less frequent schedule, like every 3-6 months, may be sufficient unless the instrument undergoes significant use or stress.

Q3: How Can I Avoid Common Measurement Errors?

- A:

- Always read the measurement at eye level to avoid parallax error.

- Ensure the instrument is on a level surface.

- For graduated cylinders, read from the bottom of the meniscus for concave liquids and the top for convex liquids.

- Pour liquids slowly to avoid creating bubbles or splashes.

Q4: Is It Safe to Measure Hot Liquids in Plastic Measuring Cups?

- A: Generally, it’s not advisable. High temperatures can cause plastic to warp or release chemicals. Use metal or heat-resistant glass for hot liquids.

Q5: Can the Same Measuring Cup Be Used for Both Dry and Liquid Ingredients?

- A: While it’s possible, it’s not recommended for precision cooking or baking. Dry ingredients should be measured in cups designed for solids, which allow for leveling off the top for an accurate measure.

Q6: How Should I Store My Graduated Cylinders and Measuring Cups?

- A: Store them in a clean, dry place, away from direct sunlight and extreme temperatures. Glass cylinders should be stored upright to avoid chipping or cracking. Plastic and metal cups can be nested for space-saving but ensure they’re completely dry to avoid mold growth.

Q7: Can I Use a Graduated Cylinder for Mixing Chemicals?

- A: Graduated cylinders are primarily for measurement, not for mixing. Mixing chemicals in them can lead to spillage or inaccurate measurements due to the narrow shape. Use a beaker or a flask for mixing.

Conclusion

Embark on a journey of precision and accuracy with our comprehensive guide on graduated cylinders and measuring cups. Whether you’re a science enthusiast, a culinary expert, or someone who values meticulousness in every task, this guide is your gateway to mastering measurements. Dive deeper into the world of precise measurements and explore a range of high-quality instruments tailored to your needs at Glasswaree.com. Revolutionize your approach to measurements today and witness the transformation in your experiments and recipes!