Ever wondered what lurks within the glass walls of your beakers and flasks? Or how the unseen imperfections in laboratory glassware can impact your scientific endeavors? The safety and reliability of glass apparatus are not just academic concerns but are critical for ensuring the integrity of scientific work and the safety of individuals involved.

Understanding the scope and purpose of safety assessments for laboratory glassware is essential. This guide aims to illuminate the path to safer laboratory practices by focusing on the comprehensive evaluation of glassware. Let’s dive into the world of laboratory safety, keeping our experiments as controlled as our enthusiasm for discovery.

What is Glassware Safety Assessment

Glassware safety assessment is a systematic approach to identifying and mitigating risks associated with using glassware in the laboratory. This involves understanding the materials and manufacturing processes, considering the operational environment, assessing the durability and strength of the glassware, checking for chemical compatibility, and ensuring cleanliness and proper sealing.

Why is Glassware Safety Assessment Important

The importance of these assessments cannot be overstated. They are not just about compliance or ticking off boxes; they are about fostering an environment where scientific inquiry and education can proceed safely and effectively. Whether it’s preventing chemical leaks, avoiding glass breakage, or ensuring accurate results, safety assessments are pivotal.

Understanding Materials and Manufacturing Processes in Laboratory Glassware

Laboratory glassware is typically made from one of several types of glass, each with its own set of properties and applications. Here are some of the most common types of glass used in laboratories, along with their manufacturing processes, safety differences, applications, and usage considerations:

- Soda-Lime Glass:

- Material Properties: Soda-lime glass is the most common type of glass, made primarily from sodium carbonate, calcium oxide, and silica. It’s relatively inexpensive but not as durable or heat-resistant as other types.

- Safety Considerations: It can withstand minor temperature changes but is prone to breakage under rapid temperature fluctuations or high heat. It’s more suitable for storage or simple experiments where temperature and chemical resistance isn’t a major concern.

- Applications: Commonly used for bottles, jars, and other containers.

- Borosilicate Glass:

- Material Properties: Borosilicate glass is known for its excellent thermal resistance and low coefficient of thermal expansion. It’s made with silica and boron trioxide. Brands like Pyrex and Duran are well-known examples.

- Safety Considerations: This type of glass is resistant to thermal shock and chemical corrosion, making it safer for experiments involving sudden temperature changes or corrosive substances. However, it can still break under extreme conditions or mishandling.

- Applications: Widely used for beakers, test tubes, and other equipment that undergoes thermal stress.

- Lead Glass:

- Material Properties: Lead glass contains lead oxide, which increases its refractive index and gives it a decorative appearance. It’s denser and has unique optical properties.

- Safety Considerations: While it’s not typically used in the experimental part of laboratories due to lead’s toxicity, it’s important to handle it with care and avoid using it for storing or processing food, drinks, or any substances that might be ingested.

- Applications: Often used for radiation shielding or optical components.

- Quartz Glass:

- Material Properties: Made almost entirely from silica, quartz glass has exceptional resistance to high temperatures and is transparent to ultraviolet light.

- Safety Considerations: Quartz glass is suitable for high-temperature applications and doesn’t react with most chemicals. However, it is more expensive and requires careful handling due to its brittleness.

- Applications: Ideal for photolithography, UV transmittance, and high-temperature processes.

- Aluminosilicate Glass:

- Material Properties: This type incorporates aluminum oxide into the silica matrix, offering higher chemical and thermal resistance than soda-lime glass.

- Safety Considerations: It’s more durable and less prone to chemical attack, making it suitable for harsher chemical environments. However, users should still be aware of its limitations and handle it with care.

- Applications: Commonly used in high-strength and chemical-resistant applications.

Manufacturing Processes:

The manufacturing process of laboratory glassware can affect its quality and safety:

- Blowing:

- Traditional glassblowing techniques are used for custom or specialized pieces. The quality and consistency depend heavily on the skill of the glassblower.

- Molding:

- Molds are used for mass production of standard laboratory glassware. This method ensures uniformity and cost-efficiency but may not be suitable for highly specialized pieces.

- Drawing:

- Tubing and rods are often made by drawing molten glass into long lengths. This method is used for items like capillary tubes and thermometers.

Usage Considerations:

- Thermal Shock: Always consider the thermal shock resistance of glassware before exposing it to rapid temperature changes.

- Chemical Compatibility: Check the chemical resistance of glassware against the substances you’ll be using. Some glass types are more resistant to acids, while others may be better for organic solvents.

- Physical Handling: Even durable glass can break with mishandling. Always use appropriate personal protective equipment and handle glassware carefully.

- Cleaning and Storage: Proper cleaning and storage are vital to maintaining the integrity and safety of glassware. Some glass may require specific cleaning agents to avoid etching or damage.

By understanding the different materials and manufacturing processes of laboratory glassware, as well as their safety considerations and applications, laboratory personnel can make informed decisions on the right type of glassware for their specific needs, ensuring both safety and efficiency in the lab.

Considering the Operational Environment

The operational environment plays a crucial role in determining the safety and efficacy of laboratory glassware. Factors like temperature, humidity, and pressure, alongside the chemical nature of substances involved, must be meticulously considered to ensure the integrity and safety of experiments. Understanding these conditions is key to preventing accidents and equipment failures. Here’s a closer look at how different types of glassware perform under varying laboratory conditions.

Performance of Laboratory Glassware under Different Environmental Conditions

| Type of Glassware | Temperature Resistance | Chemical Resistance | Pressure Resistance | Humidity Considerations | Typical Uses |

|---|---|---|---|---|---|

| Soda-Lime Glass | Low to moderate | Moderate | Low | High susceptibility | Storage, simple experiments |

| Borosilicate Glass | High | High | Moderate to high | Low susceptibility | Heating, chemical reactions |

| Lead Glass | Moderate | Low | Moderate | Moderate susceptibility | Radiation shielding, optics |

| Quartz Glass | Very high | Very high | High | Low susceptibility | UV transmittance, high-temp work |

| Aluminosilicate Glass | High | Very high | High | Low susceptibility | Chemical processing, high strength needs |

As the table demonstrates, the choice of glassware depends significantly on the operational demands of the experiment. For instance, borosilicate glass is preferred for its high thermal resistance in processes involving sudden temperature changes, while quartz glass is chosen for its exceptional performance in high-temperature and UV-related applications.

In conclusion, the operational environment is a critical aspect that must be factored into the selection and use of laboratory glassware. By understanding and respecting the limitations and strengths of different types of glassware, laboratory personnel can ensure the safety and success of their experimental endeavors. As we delve further into scientific explorations, let’s continue to consider the impact of our environment on the tools we rely upon, ensuring a safer and more efficient journey through the world of research.

Comprehensive Safety Assessment Strategies for Laboratory Glassware

Conducting a safety assessment of glassware is a crucial part of ensuring laboratory safety. Here are some methods for assessing the safety of glass instruments:

- Determine the Scope and Purpose of the Assessment: Before assessing the safety of glassware, it’s important to clarify the scope and purpose. Are all types of glassware being evaluated, or only specific types? Is the goal to ensure the instrument’s safety and reliability or to improve or optimize the instrument? Clarifying the scope and purpose helps better organize and implement the assessment.

- Understand the Materials and Manufacturing Processes of Glassware: Different types and purposes of glassware use different materials and manufacturing processes. Understanding the manufacturing materials, processes, and involved chemical components is crucial for assessing the performance and potential risks and safety hazards of glassware under specific conditions.

- Consider the Usage Environment and Operating Conditions: Glassware is affected by various environmental factors (such as temperature, humidity, pressure) and operating conditions (such as chemicals contacted, method of use) during its use. These factors should be considered in the assessment to analyze their impact on the performance and safety of the glassware.

- Assess the Strength and Durability of the Glassware: Glassware needs to withstand certain pressures, forces, and temperatures during experiments. Testing and analyzing the strength and durability of the glassware are necessary to ensure it meets experimental requirements and conditions.

- Test the Chemical Compatibility of the Glassware: Some chemicals may corrode or damage the glassware. Testing for chemical compatibility is important to determine whether harmful reactions or substances are produced during use.

- Evaluate the Cleanliness and Sealing of the Glassware: The cleanliness and sealing of glassware are important factors in its safety assessment. Poor cleanliness can affect experimental results, and poor sealing can lead to leakage or contamination of chemicals. Testing and evaluating the cleanliness and sealing of the glassware are essential.

- Analyze the Risks Associated with Using the Glassware: For different types of glassware, it’s important to analyze the potential risks associated with their use. For instance, some glassware used in high or low-temperature experiments may risk shattering or thermal shock; glassware used in chemical experiments may be prone to corrosion, wear, or breakage. Analyzing these risks helps in taking appropriate measures to reduce safety hazards during use.

- Develop Safety Guidelines and Management Systems: Based on the assessment results, develop appropriate safety guidelines and management systems. Safety guidelines include correct operation procedures, methods of use, and precautions; management systems include regular inspections, maintenance, and care of the instruments. These measures help reduce safety risks during use and ensure laboratory safety.

- Enhance Training and Education: Laboratory personnel are primarily responsible for using and managing glassware and need to be trained and educated accordingly. Training and education should cover the results of safety assessments, safe methods of use, maintenance measures, etc. Enhancing their operational skills and management levels ensures laboratory safety.

Ensuring the safety of laboratory glassware requires a multifaceted approach that encompasses understanding material properties, analyzing environmental and operational conditions, and enforcing strict testing and guidelines. By consistently applying these comprehensive safety measures, laboratories can maintain high standards of safety and efficiency, protecting both personnel and the integrity of scientific research.

Emergency Procedures and Response to Glassware-Related Accidents

When dealing with glassware in the laboratory, it’s not just about preventing accidents; it’s also about being prepared to respond effectively when they occur. Here are some essential emergency procedures and responses to consider for glassware-related accidents:

- Immediate Response to Breakage:

- Clear the Area: Ensure that the area around the broken glass is cleared of people to prevent further injury.

- Do Not Rush: Avoid the urge to quickly pick up pieces. Use appropriate tools like a brush and dustpan or forceps for larger pieces.

- Personal Protection: Wear gloves and other PPE to protect against cuts and exposure to any chemicals that may have been in the glassware.

- Chemical Spills:

- Contain and Neutralize: If the glassware contained hazardous chemicals, immediately contain the spill and use appropriate methods to neutralize it.

- Ventilate: Ensure that the area is well-ventilated to disperse any harmful vapors.

- Follow Protocol: Each laboratory should have a specific protocol for different types of chemical spills, closely follow these procedures.

- Injury Treatment:

- Minor Cuts: For small cuts, encourage bleeding to flush out any glass particles, then clean and bandage the wound.

- Serious Injuries: In case of severe cuts or embedded glass, seek medical attention immediately. Do not attempt to remove large pieces of glass embedded in the skin.

- Reporting and Documentation:

- Incident Report: Ensure that any glassware-related accident is reported to the laboratory supervisor or safety officer.

- Document: Keep a record of the accident and the response to help with future safety planning and to fulfill any regulatory requirements.

- Clean-Up and Disposal:

- Proper Disposal: Dispose of broken glass in designated sharps containers, not in regular waste bins.

- Decontamination: If the glassware contained hazardous materials, ensure that the area is properly decontaminated according to safety protocols.

- Review and Reflect:

- Incident Review: After the immediate emergency is handled, review the incident to understand what went wrong and how similar incidents can be prevented.

- Safety Training Update: Use the experience to update or reinforce safety training and protocols.

By preparing for and knowing how to respond to glassware-related accidents, laboratories can minimize the impact of these incidents and maintain a safer working environment. Regularly reviewing and practicing emergency procedures ensures that when accidents do occur, everyone is ready to respond effectively and safely.

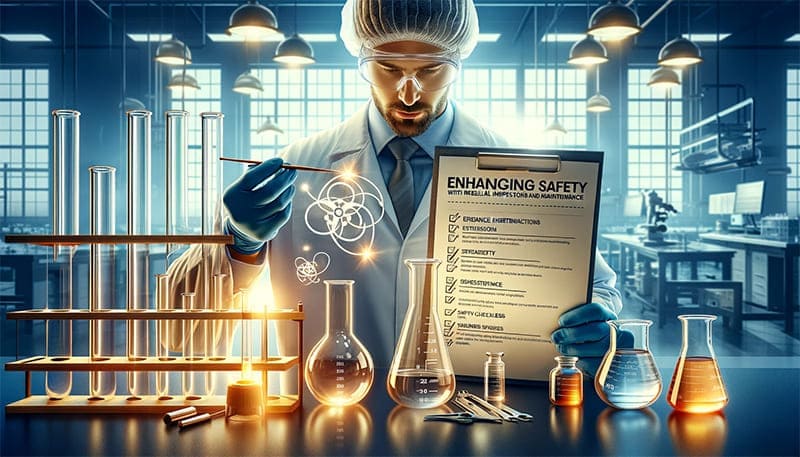

Enhancing Safety with Regular Inspections and Maintenance

To maintain the highest standards of safety, regular inspections and maintenance of glassware are imperative. Inspections can identify early signs of wear and tear, such as scratches, chips, or cracks, that might compromise the glassware’s integrity. Maintenance involves cleaning and storing glassware properly to prevent contamination or damage. By making these practices routine, laboratories can significantly reduce the risk of accidents.

The Role of Personal Protective Equipment (PPE)

While the focus is often on the glassware itself, the role of Personal Protective Equipment (PPE) in ensuring safe handling cannot be ignored. Lab coats, gloves, goggles, and face shields are essential barriers between the scientist and potential hazards. Proper use of PPE, combined with safe handling practices, drastically reduces the risk of injury from glass breakage or chemical exposure.

Implementing a Culture of Safety

Safety is not just about procedures and equipment; it’s about cultivating a culture of safety. This involves creating an environment where every member of the laboratory understands the importance of safety and feels responsible for maintaining it. Encouraging open communication about risks and safety concerns, as well as learning from incidents and near-misses, are all part of fostering a proactive safety culture.

The Importance of Proper Disposal

Even with the best care and handling, glassware will eventually reach the end of its useful life. Proper disposal is crucial to avoid injuries from broken or damaged pieces. This includes not only broken glassware but also glassware that has been contaminated with hazardous chemicals. Ensuring that all laboratory personnel are trained in the proper disposal methods is a vital component of glassware safety.

Utilizing Safety Audits and Feedback

Regular safety audits are an effective way to identify potential hazards and areas for improvement in glassware handling and procedures. Feedback from these audits, as well as input from laboratory personnel, can be invaluable in refining safety protocols and procedures. This iterative process ensures that safety measures evolve with the changing dynamics of laboratory work.

Navigating Regulatory Standards and Best Practices

Safety in the laboratory is not only a matter of best practices but also of compliance. Various regulatory bodies set standards and guidelines for handling and maintaining laboratory glassware. Familiarizing yourself with OSHA guidelines, ANSI standards, and other relevant regulations is crucial. Adherence to these standards not only ensures safety but also guarantees that your laboratory’s operations are legally compliant.

Engaging with Continuous Education

The field of laboratory science is ever-evolving, with new techniques, materials, and safety information continually emerging. Engaging in continuous education and training ensures that laboratory personnel remain updated on the latest safety protocols and glassware technologies. Workshops, seminars, and online courses are valuable resources for keeping skills sharp and knowledge current.

Embracing Technology for Safety Management

Technology can be a powerful ally in managing glassware safety. Inventory management systems help keep track of glassware usage, maintenance, and breakage history. Meanwhile, mobile apps can provide quick access to chemical compatibility charts or procedural manuals. By integrating these technological tools into the laboratory environment, you can streamline safety protocols and reduce the likelihood of human error.

Addressing the Human Factor

Even with the best procedures and the latest equipment, the human factor remains a critical component of laboratory safety. Encouraging mindfulness, promoting a detail-oriented work ethic, and fostering an environment where it’s okay to speak up about potential safety concerns are all essential. Regularly scheduled meetings to discuss safety, share experiences, and collectively troubleshoot issues can significantly enhance the safety culture.

Building a Responsive Safety Infrastructure

A responsive safety infrastructure is one that adapts to new risks and incorporates lessons from past incidents. This involves not only having a plan in place for emergencies but also regularly reviewing and updating safety protocols. Incident reporting systems, regular safety drills, and a well-maintained first aid station are all components of a robust safety infrastructure.

Conclusion

Embrace the culture of safety and vigilance in your laboratory practices. Let this guide be the beacon that illuminates your path to precision and precaution with every glassware use. Remember, a successful experiment is as much about discovery as it is about the meticulous care and handling of your tools. Be proactive, stay informed, and continuously strive for the highest standards of safety and efficiency in your scientific endeavors. Let’s safeguard our labs and shape a safer future for science together!