Have you ever considered the dangers lurking behind the everyday glassware in your chemistry lab? What risks do these seemingly benign tools carry? Glassware is integral to laboratory work, but its hazards are often underestimated. In this post, we will explore the critical aspects of glassware safety in a chemistry lab, revealing the risks and offering solutions.

Glassware safety is more than just avoiding breakage; it encompasses understanding the materials, handling procedures, and response to accidents. By grasping these elements, we can significantly reduce the likelihood of mishaps in the laboratory.

Let’s dive deeper into this crucial topic, keeping our lab experiences both informative and safe.

What Are the Primary Risks Associated with Lab Glassware

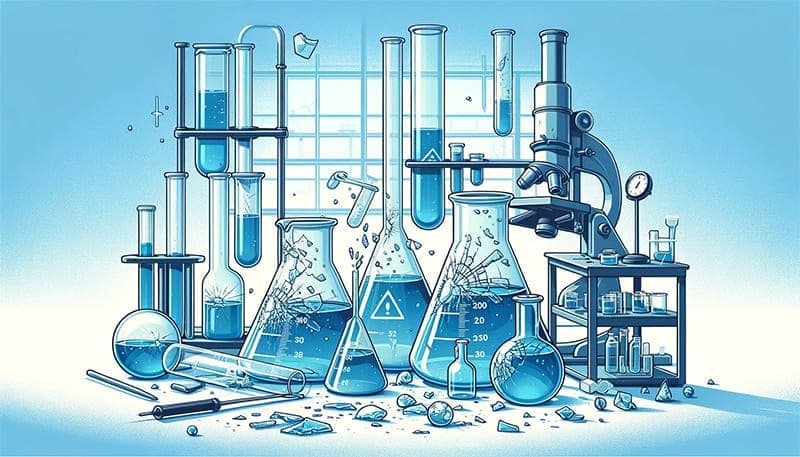

In a laboratory, glassware can pose several risks. The most common issues are breakage, chemical reactions, and contamination. Understanding these risks is the first step to mitigating them.

Breakage: More Than Just a Mess

Glassware breakage is a frequent lab hazard. It can result from improper handling, thermal stress, or mechanical impact. Broken glass can cause injuries and contaminate experiments.

Chemical Reactions: A Hidden Danger

Certain chemicals can react with the glass, leading to dangerous situations. Understanding the chemical compatibility of your glassware is crucial to prevent these reactions.

Contamination: Compromising Your Results

Improperly cleaned glassware can retain residues, leading to cross-contamination. This is particularly problematic in sensitive experiments where purity is paramount.

Thermal Shock: A Sudden Breakdown

Thermal shock in lab glassware occurs when it undergoes rapid temperature changes, leading to cracks or shattering. This not only ruins experiments but also poses a physical hazard. Gradual heating or cooling is key to preventing these incidents.

Improper Use: Beyond Design Limits

Using glassware for unintended purposes, like substituting a beaker for a volumetric flask, can lead to inaccurate results and potential hazards. This improper use stresses the importance of choosing the right glassware for each specific task.

Chemical Corrosion and Erosion: Hidden Dangers to Glassware

Chemical corrosion and erosion are less visible but critical risks for lab glassware. Strong acids, bases, and certain organic solvents can react with glass silicates, leading to surface roughening, micro-cracks, or structural weakening. This not only compromises the integrity of the glass but also risks internal contamination, affecting experimental accuracy. Understanding and matching chemical compatibility with glassware is essential to prevent these subtle yet significant damages.

Overfilling: The Spill and Splash Hazard

Overfilling glassware can cause spills, leading to chemical exposure risks and potential slips. It’s essential to respect the maximum capacity markings to ensure safety and accuracy in measurements.

Pressure Build-Up: The Invisible Threat

In closed glassware systems, certain reactions or heating methods can cause pressure build-up, risking explosions. Proper venting techniques are crucial to prevent such dangerous scenarios.

Ergonomic Risks: The Strain of Handling

Handling large or heavy glassware, especially when filled, presents ergonomic risks. Improper handling can lead to muscle strains, fatigue, or accidents. Understanding and applying correct handling and lifting techniques are vital for safety.

Implementing SOPs for Lab Glassware: A Step-by-Step Guide to Safety

In the realm of laboratory safety, the establishment and adherence to Standard Operating Procedures (SOPs) for using glassware are paramount. These SOPs serve as a detailed guide to ensure safe and efficient handling of lab glassware. Let’s delve into the specific steps that should be included in these SOPs to enhance safety practices in the laboratory.

1. Pre-Use Inspection

- Check for Damage: Before using any piece of glassware, inspect it for cracks, chips, or any signs of stress. Even small imperfections can lead to failures under thermal or chemical stress.

- Cleanliness: Ensure that the glassware is clean. Residual chemicals from previous use can cause unwanted reactions or contaminate experiments.

2. Cleaning Protocols

- Appropriate Cleaning Agents: Use the correct cleaning agents for different types of glassware. Some materials may require mild detergents, while others might need more rigorous cleaning methods.

- Rinsing and Drying: After cleaning, rinse glassware thoroughly with distilled water. Ensure it’s completely dry before use, especially if it will be heated.

3. Handling and Usage

- Safe Transportation: Always use a tray or a carrier when transporting glassware, especially if it contains chemicals.

- Avoid Overfilling: Never fill glassware beyond its recommended capacity to prevent spills and potential breakage.

- Heating and Cooling: Gradually heat and cool glassware to prevent thermal shock. Use water baths, heating mantles, or ovens as appropriate.

4. Chemical Handling

- Chemical Compatibility: Check the compatibility of the glassware with the chemicals being used. Certain glass types can react or weaken when exposed to specific chemicals.

- Venting: When mixing or heating volatile or reactive chemicals, ensure proper venting to avoid pressure build-up.

5. Post-Use Care

- Cool Down: Allow glassware to cool down naturally; do not subject it to rapid temperature changes.

- Proper Cleaning: Clean the glassware immediately after use following the prescribed cleaning protocols.

- Storage: Store glassware in a secure, organized manner. Heavy items should be on lower shelves, and fragile items should be in areas where they are less likely to be knocked over.

Adhering to these SOPs is not just a procedural formality but a crucial step towards ensuring safety in the laboratory. By meticulously following these guidelines, lab personnel can significantly reduce the risks associated with the use of glassware, maintaining a safe and productive research environment.

Emergency Protocols for Glassware-Related Accidents: A Guide for Lab Safety

An essential addition to our discussion on laboratory safety is the outline of specific emergency protocols for glassware-related accidents. This guidance is crucial in preparing lab personnel for unexpected situations involving glassware, ensuring a prompt and effective response to minimize harm and disruption.

Response to Cuts from Broken Glass

- Immediate Action: In case of a cut from broken glass, the first step is to ensure safety from further harm. Safely remove any remaining glass pieces.

- Wound Care: Clean the wound with mild soap and water. Apply pressure with a sterile bandage to stop bleeding.

- Seek Medical Attention: For deep or large cuts, or if the bleeding does not stop, seek medical attention immediately.

Dealing with Chemical Exposure due to Glassware Failure

- Containment: If a chemical spill occurs due to glassware breakage, contain the area immediately to prevent further spread.

- Personal Safety: Use appropriate personal protective equipment (PPE) like gloves and safety goggles while handling the spill.

- Spill Cleanup: Follow the lab’s specific spill response protocol. Use appropriate neutralizers and absorbents for the chemical involved.

General First Aid Measures

- First Aid Kits: Ensure that first aid kits are easily accessible in the laboratory. These should include bandages, disinfectants, and other basic medical supplies.

- Training: Regular training on basic first aid measures, including how to treat cuts and chemical exposure, is essential for all lab personnel.

When to Seek Medical Attention

- Severity Assessment: For any injury or exposure, assess the severity. If there’s any doubt about the seriousness of the injury or exposure, err on the side of caution and seek medical attention.

- Report and Document: Report the incident to the appropriate lab authority. Documenting the incident helps in understanding the cause and preventing future occurrences.

Preparedness for glassware-related accidents is a critical aspect of lab safety. By understanding and implementing these emergency protocols, lab personnel can effectively handle accidents, ensuring their safety and that of their colleagues. Remember, a prompt and knowledgeable response can make a significant difference in the outcome of any laboratory accident.

The Role of Lab Inspections and Safety Audits in Glassware Management

A pivotal aspect of maintaining a safe laboratory environment involves regular lab inspections and safety audits, particularly concerning the use and maintenance of glassware. This process is integral to identifying potential risks and ensuring consistent adherence to safety protocols.

Importance of Routine Lab Checks

- Regular Inspections: Conducting routine inspections helps in identifying any damaged or compromised glassware before it can pose a risk. This proactive approach is key in preventing accidents.

- Updating Inventory: Keeping an up-to-date inventory of all glassware allows for better management and timely replacement of items. It also aids in tracking usage patterns and potential issues.

Ensuring Compliance with Safety Standards

- Safety Audits: Regular safety audits are essential to ensure that all lab practices, including those related to glassware use, meet the required safety standards. This includes evaluating the effectiveness of existing SOPs and emergency protocols.

- Continuous Improvement: These audits provide opportunities for continual improvement in safety practices, highlighting areas that need more attention or new strategies.

Regular lab inspections and safety audits play a critical role in reinforcing a culture of safety, particularly regarding glassware use in laboratories. By consistently evaluating and improving safety practices, laboratories can significantly reduce the risks associated with glassware, ensuring a safer environment for all personnel.

FAQ: Navigating Glassware Safety in the Laboratory

To further enrich our comprehensive guide on glassware safety in the lab, we’ve compiled a list of frequently asked questions (FAQs). These questions are designed to address common queries and concerns, providing valuable insights that align closely with our article’s theme.

What is the Best Way to Handle Broken Glass in the Lab?

The safest approach is to use a brush and dustpan, not your hands, to clean up broken glass. Dispose of it in a designated sharps container to prevent injury.

How Can I Determine if Glassware is Safe for a Specific Chemical?

Consult the Material Safety Data Sheet (MSDS) for the chemical in question. It will provide information on chemical compatibility and the appropriate type of glassware to use.

What Should I Do If I Notice a Crack in Glassware?

If you find a crack, no matter how small, discontinue use of the glassware immediately. Cracked glassware is a significant safety hazard and should be replaced.

Are There Specific Types of Glassware for Different Laboratory Applications?

Yes, different types of glassware are designed for specific purposes. For example, Erlenmeyer flasks are suitable for mixing and heating, while volumetric flasks are for precise volume measurements. Using the correct type for your application is crucial for safety and accuracy.

How Often Should Laboratory Glassware be Replaced?

There’s no set rule, but it’s important to replace glassware that shows signs of wear, chemical etching, or cloudiness. Regular inspections can help determine when it’s time for replacement.

Can Safety-Coated Glassware Prevent Injuries?

Safety-coated glassware can reduce the risk of injury as it’s designed to contain glass and spills if breakage occurs. It’s particularly useful for handling hazardous substances.

Conclusion

This article serves as an essential guide to understanding and navigating the risks associated with laboratory glassware. By applying the information and practices outlined, lab personnel can significantly enhance safety in their work environment. Let this article be your stepping stone towards fostering a culture of safety and vigilance in the laboratory. Remember, knowledge and precaution are the keys to preventing accidents, so stay informed, stay safe, and continue exploring the fascinating world of science with confidence and care.