Have you ever wondered why drying glassware in a lab is such a meticulous process? Why can’t we just leave it to air dry, or maybe give it a quick wipe? These questions may seem trivial, but in a laboratory setting, the way we dry glassware can significantly impact the accuracy and reliability of experimental results.

Glassware drying is not just about removing water; it’s about ensuring that no residue interferes with your experiments. It’s a crucial step in maintaining the integrity of laboratory work. But how exactly does one go about it effectively?

Maintaining the purity of your experiments starts here.

Understanding the Importance of Proper Glassware Drying

Why is Glassware Drying Crucial in Labs? To grasp the importance of proper glassware drying, it’s essential to understand its role in laboratory accuracy and safety. Glassware used in labs isn’t just any ordinary glass; it’s a vessel for potentially groundbreaking scientific experiments.

Diving into the Methods of Glassware Drying

Natural Air Drying is the simplest method, involving leaving the washed glassware in a clean, dry, and ventilated space. This method is time-consuming and not suitable for urgent or bulk drying needs.

Oven Drying: Washed glassware should be freed of excess water and then placed in an electric drying oven. The temperature in the oven should be maintained at 105–120°C for about an hour. This method is suitable for most types of glassware. For glassware with solid glass stoppers or thick walls, gradual temperature increase is important to prevent cracking. Such glassware should not be placed in the oven for drying. Hard glass test tubes can be dried with an alcohol lamp, starting from the bottom and keeping the open end downward to prevent the condensation of water droplets inside, which could cause the tube to burst. Once all droplets are gone, turn the open end upwards to eliminate any remaining steam.

Hot/Cold Air Blow Drying: For instruments that require quick drying or are too large for an oven, a blow-drying method can be used. Typically, a small amount of ethanol, acetone (or finally ether) is poured into the instrument after the water has been drained, and then the solvent is shaken out (it should be recycled). Next, use a hairdryer, starting with cold air for 1-2 minutes. When most of the solvent has evaporated, switch to hot air until completely dry, and then use cold air again to blow out the remaining vapors, preventing them from condensing inside the container.

Infrared Drying employs infrared radiation to rapidly remove moisture. This method is effective and suitable for quick drying of large quantities of glassware.

The Impact of Glassware Material on Drying Method Selection

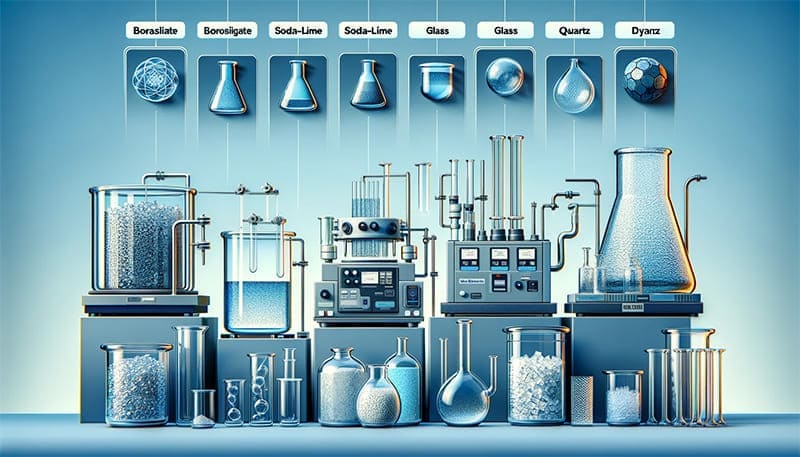

The type of glassware material – be it borosilicate, soda-lime glass, or quartz – significantly influences the choice of drying methods. Each material exhibits distinct thermal and chemical resistance properties, making some materials more suited to certain drying techniques than others. Knowledge of these material characteristics is crucial in choosing the most effective and safest drying method for each type of glassware. Here’s a breakdown:

- Borosilicate Glass: Known for its high thermal resistance and excellent chemical stability, borosilicate glass can safely undergo more rigorous drying methods like oven drying, microwave drying, and even infrared drying without the risk of damage or alteration.

- Soda-Lime Glass: This type of glass, commonly found in lab settings, offers moderate thermal and chemical resistance. Therefore, it is best suited for gentler drying methods such as natural air drying or controlled oven drying to prevent thermal stress and potential damage.

- Quartz Glass: With its exceptionally high thermal and chemical resistance, quartz glass can withstand advanced drying techniques like ultrasonic drying, vacuum drying, or lyophilization, making it ideal for delicate and precision experiments.

The material of the glassware in a laboratory is a key factor in determining the appropriate drying method. By tailoring the drying technique to the type of glassware, laboratories can not only ensure the longevity and integrity of their glassware but also maintain the accuracy and reliability of their experiments. This understanding is a vital component in the pursuit of excellence in laboratory practices, contributing significantly to the quality and consistency of scientific research.

Techniques and Tips for Effective Drying

Air Drying Method: For non-urgent glassware, after rinsing with pure water, invert them in a dust-free area to let them air dry naturally. Storing them on racks with slanted nails or in ventilated glass cabinets is advisable.

Oven Drying Method: Washed glassware, after being freed from most water, should be dried in an electric oven at 105–120°C for about an hour. This method suits most general lab instruments. However, glassware with solid stoppers or thick walls requires gradual heating to prevent cracking.

Blow Drying with Hot/Cold Air: For instruments needing quick drying or those too large for an oven, the blow-drying method is effective. Clean the glassware with a small amount of ethanol, acetone, or ether, shaking out the solvent (which should be recycled), and then use a blow dryer. Start with cold air for 1-2 minutes, switch to hot air until fully dry, and finish with cold air to prevent condensation.

Troubleshooting Common Issues in Glassware Drying Processes

In the pursuit of laboratory excellence, understanding how to address common issues encountered during the glassware drying process is as important as knowing the drying techniques themselves. This section aims to provide practical solutions to some of the frequently faced challenges, ensuring a smooth and effective drying process.

Residue Formation After Drying

- Problem: Residues appearing on glassware post-drying, affecting the purity of subsequent experiments.

- Solution: Ensure thorough cleaning before drying. Use deionized or distilled water for the final rinse. If residues persist, consider using a mild acid wash followed by ample rinsing.

Glassware Cracking or Breaking

- Problem: Glassware cracking or breaking during the drying process, especially in ovens or during rapid drying methods.

- Solution: Gradually increase the temperature for heat-based drying methods. Avoid sudden temperature changes and ensure the glassware is compatible with the chosen drying method. For delicate glassware, prefer gentler methods like air drying or vacuum drying.

Inefficient Drying

- Problem: Glassware remains damp or takes too long to dry.

- Solution: Increase airflow or temperature within safe limits for the specific glassware type. For air drying, ensure that the environment is dry and well-ventilated. For oven drying, check for uniform temperature distribution.

Water Spots and Streaks

- Problem: Water spots or streaks left on glassware, often due to mineral content in the water used for washing or rinsing.

- Solution: Use distilled or deionized water for the final rinse. If using tap water, consider a final rinse with ethanol or acetone to prevent spotting.

Glassware Overheating

- Problem: Overheating of glassware, especially in high-temperature drying methods like ovens or microwave drying.

- Solution: Monitor the temperature closely and adhere to the recommended temperature ranges for each glass type. Use a thermometer to ensure accuracy.

Contamination Risk

- Problem: Risk of contamination, either from the drying environment or leftover residues.

- Solution: Ensure that drying racks and cabinets are clean and free from contaminants. Regularly inspect and maintain drying equipment to prevent any contamination risk.

By addressing these common issues, laboratory personnel can enhance the efficiency and safety of the glassware drying process. It’s important to continuously monitor and evaluate the effectiveness of your chosen methods, making adjustments as needed to ensure the highest standard of laboratory practice.

Key Considerations in Lab Glassware Drying

- Choose the appropriate drying method based on the experiment’s requirements and the material and shape of the container to ensure effective drying and the safety and accuracy of experimental results.

- Control of Drying Temperature and Time: Different types of glassware, with varying materials and shapes, require specific drying temperatures and times. Excessive temperature and prolonged drying time may cause damage or deformation of the glassware, so adjustments should be made according to the actual situation.

- Stability of Glassware: During the drying process, glassware may expand or contract due to temperature changes, leading to instability or even breakage. Therefore, it’s important to ensure the stability of the glassware and avoid drastic temperature changes.

- Avoiding Residue Effects: If there are residues in the glassware, they can affect the drying efficiency and the results of the experiment. Therefore, it is important to thoroughly clean any residues before drying.

- Storage of Glassware: After drying, store the glassware in a dry, cool, and ventilated place to prevent moisture absorption or contamination. Handle them gently to avoid collisions or damage.

- Personal Safety and Environmental Protection: Pay attention to personal safety and environmental protection during the drying process. Wear gloves, avoid contact with hot surfaces, and properly dispose of waste to ensure smooth experimental procedures. Also, be mindful of environmental pollution sources to prevent impacting experimental results and safety.

In conclusion, correctly drying glassware is critical for the accuracy and safety of laboratory experiments. Understanding various drying methods and precautions enhances their utility in experiments. Remember to prioritize personal safety and environmental considerations to ensure smooth laboratory operations.

Innovations in Glassware Drying Technology

Advancements in drying technology have introduced a variety of methods that cater to the diverse needs of modern laboratories. Alongside traditional techniques, these innovations offer enhanced efficiency and safety for drying laboratory glassware.

Vacuum Drying represents a significant development, where glassware is placed in a vacuum chamber. This method effectively removes moisture without the need for high temperatures, making it particularly suitable for delicate glassware that might be susceptible to heat damage.

Ultrasonic Drying uses high-frequency sound waves to rapidly evaporate moisture. This technique is both efficient and gentle, ensuring the integrity of the glassware is maintained without exposing it to excessive heat or mechanical stress.

Adding to these methods are Microwave Drying and Lyophilization (Freeze-Drying). Microwave Drying harnesses microwave radiation to quickly heat and evaporate water from glassware. This method stands out for its rapid drying capability, greatly reducing waiting times in busy laboratory environments.

Lyophilization, on the other hand, involves freezing the glassware with any residual liquid and then reducing the surrounding pressure to allow the frozen water to sublimate directly from the solid phase to the gas phase. This technique is particularly effective for drying delicate or heat-sensitive materials, as it eliminates the risk of thermal degradation.

Together, these innovative drying technologies – Vacuum Drying, Ultrasonic Drying, Microwave Drying, and Lyophilization – provide laboratories with a comprehensive toolkit for efficiently and safely preparing glassware for experimental use, catering to a wide range of materials and experimental requirements.

The Art of Balancing Efficiency with Safety

Balancing speed and safety in glassware drying is an art. While quick drying methods are tempting, they must be used judiciously to avoid thermal stress on the glassware. Gradual heating and cooling phases are essential to prevent cracks or breakage.

Environmental Considerations in Glassware Drying

Environmentally conscious drying practices are gaining importance. Using energy-efficient dryers and recycling solvents like ethanol or acetone during the blow-drying process are steps towards a more sustainable lab environment.

Tips for Best Practices in Glassware Drying

- Inspect Glassware Before Drying: Check for cracks or chips. Damaged glassware can be hazardous when subjected to temperature changes.

- Label Heat-Sensitive Glassware: Some glassware cannot withstand high temperatures. Labeling them helps avoid accidental damage.

- Use Appropriate Drying Racks: Ensure glassware is securely placed on racks that prevent tipping or overcrowding.

- Monitor Drying Process: Especially in ovens or when using hot air, keep a close eye to prevent overheating.

- Cool Down Gradually: After drying, allow glassware to cool down slowly to room temperature before storage or use.

Integrating Glassware Drying into Laboratory Workflow and Protocols

Effective laboratory management includes the integration of glassware drying procedures into the overall workflow. This integration is key to ensuring consistency, efficiency, and safety in the laboratory environment. By establishing clear and detailed protocols for when and how to dry different types of glassware, based on their specific use and urgency, laboratories can streamline their operations.

The development of these protocols involves considering the nature of the experiments, the types of glassware used, and their material properties. It is important to determine the most suitable drying method for each type of glassware to prevent damage and ensure the accuracy of experimental results. This planning also includes scheduling drying times to align with laboratory workflows, ensuring that glassware is available when needed without causing bottlenecks in the process.

Furthermore, integrating these drying procedures into laboratory training programs is crucial. It ensures that all personnel are aware of the best practices and safety measures associated with glassware drying. Regular reviews and updates of these protocols are also essential to incorporate new technologies and methods, ensuring the laboratory remains at the forefront of efficiency and safety.

In summary, the incorporation of glassware drying protocols into laboratory workflows is not just a matter of maintaining equipment. It is about enhancing the overall functionality and productivity of the laboratory, minimizing errors and delays, and upholding the highest standards of experimental integrity.

Conclusion

Mastering the art of glassware drying is pivotal in achieving laboratory excellence. We encourage laboratory professionals to not only adopt these best practices but also to continuously seek advancements and innovations in drying technology. Stay informed, stay efficient, and lead the way in upholding the highest standards of accuracy and safety in scientific research. Your dedication to these practices is instrumental in pushing the boundaries of scientific discovery.