Have you ever wondered how delicate substances are distilled and refined in laboratories? What kind of magic lies behind the transformation of vapors back into liquid form? The answer lies in a seemingly simple yet fascinating piece of equipment: the condenser tube.

Condenser tubes play a pivotal role in laboratory experiments, specifically in the processes of distillation and reflux. Their ability to efficiently cool and condense gases into liquids is indispensable in the realms of chemical and biological research. This blog post delves into the world of condenser tubes, exploring their construction, function, and the significant impact they have on laboratory techniques.

The principle behind condenser tubes is straightforward but ingenious. They utilize the concept of heat exchange to cool gaseous substances, transforming them back into liquid form. This process is crucial in various laboratory procedures, particularly in distillation and organic synthesis.

Understanding the Construction of Condenser Tubes

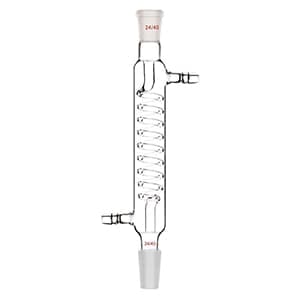

A condenser tube uses the principle of heat exchange to cool and condense gaseous substances into liquids. It’s a glass instrument used for facilitating condensation or reflux in laboratory settings. Typically, it consists of two glass tubes, one inside the other, with the smaller glass tube passing through the larger one. The inner tube has connectors at both ends for attachment to other experimental devices, allowing hotter gases or liquids to flow through and condense. The outer tube usually has two openings, one on each side, for connecting plastic tubing that carries the cooling substance (like water). When used, the lower opening of the outer tube is often connected to a faucet so that water naturally rises when heated, filling the outer tube and expelling air, making operation simple. For improved cooling, the flow direction in the inner and outer tubes can be made opposite, enhancing heat exchange and maintaining consistent temperature differences, which also helps in preventing damage to the condenser.

The Role of Condenser Tubes in Laboratories

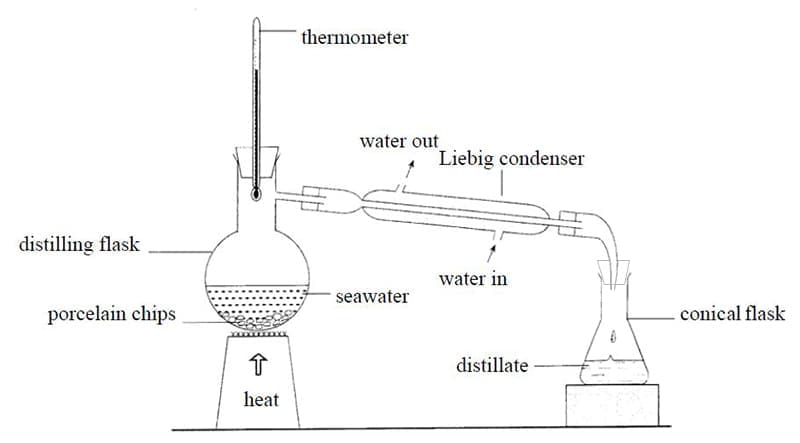

The primary function of a condenser tube is to transfer heat from a high-temperature substance to a low-temperature one, thereby achieving a cooling effect. In laboratories, condenser tubes are commonly used for distilling liquids or in organic synthesis, serving both condensation and reflux functions. Specifically, they are used to distill and separate organic substances in liquid mixtures, or for condensing and refluxing reactants and products. By using a condenser tube, high-temperature substances are cooled to lower temperatures, resulting in purer and more concentrated substances.

Historical Development of Condenser Tubes

The journey of condenser tubes from their early inception to the sophisticated designs we see today is a fascinating story of scientific progress and innovation. Initially, the concept of condensation in scientific experiments was primitive, relying on basic methods to cool vapors into liquids. However, the need for more efficient and controlled processes led to the development of the first condenser tubes.

In the early days, materials like copper and brass were common in the construction of condenser tubes. These materials, while effective for heat transfer, had limitations in terms of chemical resistance and durability. The breakthrough came with the advent of glass condensers, which provided better visibility of the condensation process and were more resistant to chemical reactions.

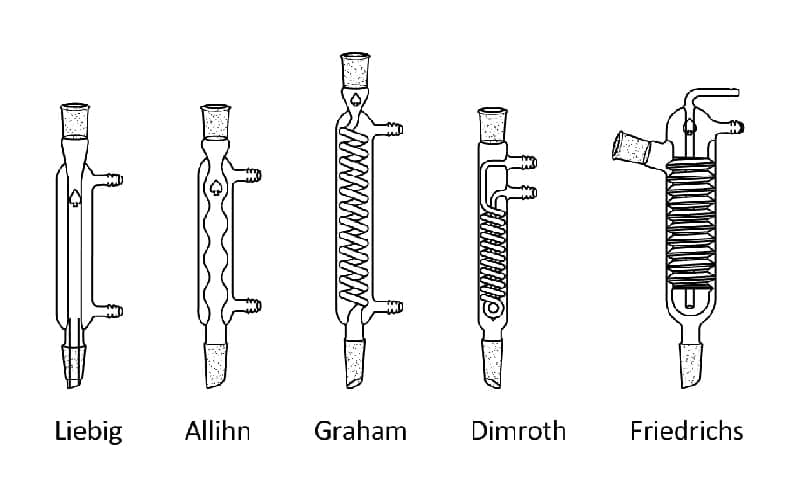

One of the earliest and most significant developments was the Liebig condenser, designed by the German chemist Justus von Liebig in the 19th century. This design featured a straight glass tube within a larger glass tube, allowing for efficient cooling of vapors through direct contact with a cooling agent, usually water. This design became a staple in laboratories for its simplicity and effectiveness.

As chemistry evolved, so did the design of condenser tubes. The 20th century witnessed the introduction of various types of condensers, each tailored for specific purposes. The Graham condenser, with its coiled inner tube, provided a larger surface area for cooling, making it ideal for delicate distillation processes. The Allihn condenser, with its bulbous design, enhanced the condensation process for certain types of chemicals.

Material advancements also played a crucial role in the evolution of condenser tubes. The introduction of borosilicate glass, known for its durability and thermal resistance, marked a significant improvement. This material could withstand high temperatures and aggressive chemicals, making it ideal for a wide range of laboratory applications.

Today, condenser tubes are more diverse and efficient than ever. Modern designs incorporate advanced materials like high-quality borosilicate glass and specialized coatings to enhance their performance. Computer-aided design and manufacturing techniques have also allowed for more precise and complex structures, catering to the ever-growing demands of scientific research.

The historical development of condenser tubes reflects not just the advancements in materials and design but also the evolving needs of scientific research. From simple copper coils to sophisticated glass apparatuses, these tubes have been integral to the progress of experimental science, enabling researchers to conduct more complex and precise experiments. As science continues to advance, the design and functionality of condenser tubes are expected to evolve further, continuing their legacy as essential tools in the pursuit of knowledge.

Material Science Behind Condenser Tubes

The effectiveness of condenser tubes in laboratory settings is largely attributable to the materials used in their construction, which are carefully chosen for their specific properties. Primarily, borosilicate glass stands out as a key material due to its exceptional qualities.

Borosilicate Glass

This type of glass is the most commonly used material in the making of condenser tubes. Its popularity stems from several inherent properties:

- Thermal Resistance: Borosilicate glass can withstand significant temperature fluctuations without cracking. This property is essential for condenser tubes, which often experience rapid temperature changes during distillation processes.

- Chemical Stability: It is highly resistant to chemical corrosion, making it ideal for use with a wide range of substances, including aggressive chemicals.

- Durability: Borosilicate glass is more durable and less prone to breakage compared to regular glass, making it a safer choice in the laboratory environment.

- Transparency: The clear nature of this glass allows for easy monitoring of the condensation process.

Other Materials

While borosilicate glass is predominant, other materials are also used in specific types of condensers or for certain parts:

- Polytetrafluoroethylene (PTFE): Used in joints and seals for its non-reactive nature and durability.

- Stainless Steel: Selected for its strength and resistance to heat and chemicals, stainless steel is sometimes used in the framework of condenser tubes or in cooling coils.

Advancements in Material Science

Ongoing research and development in material science continually lead to improvements in condenser tube materials. Innovations might include the use of composite materials for enhanced durability, or coatings that improve heat transfer efficiency and chemical resistance.

Understanding the material science behind condenser tubes is crucial for laboratory professionals. This knowledge not only aids in the proper selection and use of condenser tubes but also informs maintenance and safety practices. As material technology advances, we can expect even more efficient and resilient condenser tubes, further revolutionizing laboratory techniques.

Exploring the Diversity of Condenser Tubes in Laboratories

The world of laboratory condensation techniques is marked by a variety of specialized condenser tubes, each designed to cater to specific requirements. The following table offers a glimpse into this diversity, showcasing the distinct designs, applications, and considerations associated with different types of condenser tubes.

Understanding these variations is key to optimizing the efficiency and accuracy of laboratory experiments. From the coiled design of the Graham Condenser to the bulbous structure of the Allihn, each type serves a unique purpose in the scientific quest for precision and reliability.

The diversity in the design and application of condenser tubes is a testament to the intricate and evolving nature of laboratory science. By selecting the appropriate condenser tube for each specific application, researchers can ensure accurate and effective results in their experimental endeavors.

Guidelines for Effective Use of Condenser Tubes in Laboratory Settings

In laboratory environments, the correct handling and operation of condenser tubes is crucial for achieving accurate experimental outcomes. The following guidelines provide a comprehensive overview of the necessary steps and precautions for the effective use of condenser tubes, ensuring their optimal performance and longevity. Let’s delve into the details of these procedures.

How to Properly Use Condenser Tubes?

Using a condenser tube correctly is paramount for the success of laboratory experiments. It involves several steps:

- Preparation Stage:

- Check the condenser tube for any damage, cracks, or impurities.

- Choose an appropriate support to place the condenser tube, like a stand or lab-specific holder.

- Install the condenser tube on the support and connect it to the substance to be condensed using tubing.

- Operation Stage:

- Start the flow of cooling water into the condenser tube.

- Begin the condensation process by heating the substance to produce steam or gas, which will then condense into liquid in the tube.

- Closely observe and record the flow rate of the condensed liquid. If there are anomalies, stop immediately to check and address the issue.

- Collect the condensed liquid in a suitable container.

- Post-operation:

- Clean the condenser tube to remove residue and dirt.

- Dry the tube thoroughly before storage.

- Store the condenser tube in a dry, cool place away from direct sunlight or high temperatures.

Safety Precautions:

When using a condenser tube, it’s important to ensure stability and control the flow of cooling water. Keep a close watch on the flow rate of the liquid and record relevant data. Handle the collected liquid safely to avoid burns or other hazards. After use, clean and dry the condenser tube properly. Be cautious about electrical hazards if using electric heating devices, and wear protective gear when dealing with toxic or corrosive liquids. Ensure the setup is airtight to prevent leaks. Clean up thoroughly after experiments to avoid leaving hazardous materials behind. Avoid subjecting the condenser tube to sharp impacts or vibrations to maintain its accuracy and lifespan. Always understand and follow the proper usage guidelines and safety measures.

Condenser tubes are essential in laboratories for their simple structure and significant function. Proper use and maintenance can extend their lifespan and improve the accuracy of experimental results.

Real-World Applications

Condenser tubes are not just theoretical tools; their practical applications in both experimental and industrial settings underscore their critical role in various scientific and manufacturing processes. Here are a couple of classic examples that highlight their importance:

- Pharmaceutical Compound Distillation:

- Context: In the pharmaceutical industry, the purity of compounds is paramount. A common process in the production of medicines involves the distillation of raw chemical compounds to isolate active pharmaceutical ingredients (APIs).

- Role of Condenser Tubes: Condenser tubes are integral in this process. They are used to cool and condense the vaporized compounds, ensuring that only the desired product is collected. The precise temperature control offered by condenser tubes is crucial for the separation of compounds with close boiling points.

- Outcome: This application not only demonstrates the efficiency of condenser tubes in separating complex mixtures but also underscores their role in ensuring the safety and efficacy of pharmaceutical products.

- Environmental Testing – Air Quality Analysis:

- Context: Monitoring and analyzing air quality is vital for environmental protection. This often involves collecting and analyzing airborne contaminants, which can be challenging due to their volatile nature.

- Role of Condenser Tubes: Condenser tubes are used in the process of air sampling where they condense airborne water vapor and contaminants. This condensation allows for more accurate measurement and analysis of pollutants present in the atmosphere.

- Outcome: The use of condenser tubes in this context is essential for obtaining precise data, which is critical for environmental research and forming policies to protect air quality.

These examples illustrate the versatility and effectiveness of condenser tubes in diverse applications. From the meticulous requirements of pharmaceutical manufacturing to the broad-reaching implications of environmental research, condenser tubes prove to be indispensable tools in both laboratory and industrial contexts. Their ability to precisely control the condensation process makes them invaluable in any operation where separation and purification are key.

Maintenance and Troubleshooting

Effective maintenance and timely troubleshooting are essential for ensuring the longevity and proper functioning of condenser tubes in laboratory settings. Here, we explore the common maintenance practices, potential issues, and their solutions.

Routine Maintenance

- Cleaning: Regular cleaning is crucial. After each use, rinse the condenser tube with distilled water to remove any residual substances. For tougher residues, use appropriate solvents followed by distilled water.

- Drying: Post-cleaning, it’s important to dry the condenser tube completely to prevent water stains or buildup of residues. Air drying or using a drying cabinet are common methods.

- Inspection: Periodically inspect for any signs of wear, cracks, or breakage, particularly at the joints and seals. Even minor damages can affect the efficiency of the condenser tube.

Common Issues and Troubleshooting

- Clogging:

- Cause: Residue buildup or precipitates from the condensed substances can clog the tube.

- Solution: Regular cleaning and using proper filtration before the condensation process can prevent this. For existing clogs, use specialized cleaning brushes or solvents to dissolve the blockage.

- Leaks:

- Cause: Leaks typically occur at the joints or due to cracks in the glass.

- Solution: Ensure all fittings and connections are secure before each use. If a crack is detected, the condenser tube must be replaced.

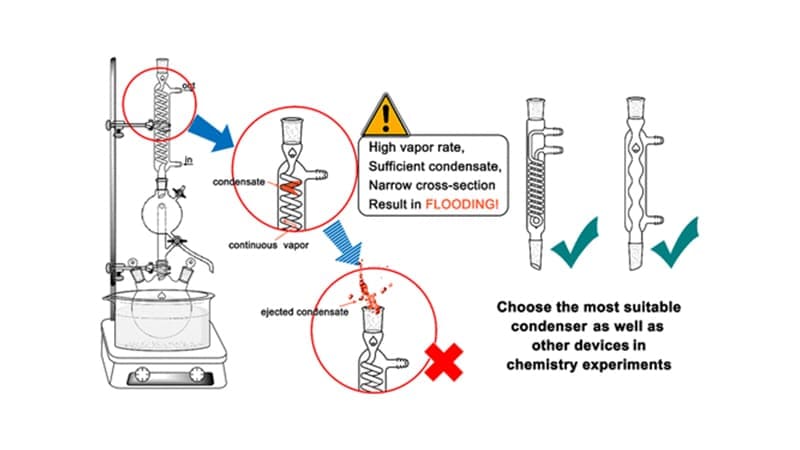

- Inefficient Condensation:

- Cause: This can result from inadequate cooling water flow or incorrect assembly.

- Solution: Check the water flow rate and adjust as necessary. Ensure that the condenser tube is set up correctly, with the cooling medium flowing counter to the direction of the vapor flow.

- Thermal Stress:

- Cause: Sudden temperature changes can cause stress fractures in the glass.

- Solution: Gradually adjust temperatures during experiments and avoid exposing the glass to sudden extreme temperature changes.

Preventive Measures

- Proper Storage: Store the condenser tubes in a secure, upright position, preferably in a padded or cushioned environment to prevent physical damage.

- Regular Calibration: For condenser tubes integrated with temperature-sensitive equipment, regular calibration ensures accurate readings and performance.

- Training: Proper training for all laboratory personnel in handling and maintaining condenser tubes is crucial to prevent mishandling and accidents.

By adhering to these maintenance and troubleshooting guidelines, the functionality and lifespan of condenser tubes can be significantly extended, ensuring they remain reliable tools in laboratory experiments. Regular care and preventive measures are key to avoiding common issues and ensuring smooth operation.

Safety Standards and Regulations

The use of condenser tubes in laboratory environments is governed by a set of safety standards and regulations designed to protect users and ensure effective and hazard-free operations. These standards are crucial for maintaining a safe laboratory environment, especially when dealing with high temperatures, chemicals, and glassware. Here is an outline of the key safety standards and regulations:

- Chemical Handling and Exposure:

- Laboratories must adhere to regulations regarding the handling of chemicals, particularly those that are volatile or hazardous. This includes proper ventilation, use of fume hoods, and adherence to Material Safety Data Sheets (MSDS) for each chemical used.

- Personnel should be trained in the proper handling of chemicals and the use of condenser tubes in chemical processes, including the risks of chemical reactions and the proper disposal of chemical waste.

- Glassware Safety:

- Condenser tubes, being primarily made of glass, fall under glassware safety regulations. This includes regular inspection for damage, proper handling to avoid breakage, and correct setup in experimental apparatus.

- The use of personal protective equipment (PPE) such as lab coats, gloves, and safety goggles is mandatory when handling glassware to protect against cuts and exposure to chemicals.

- Temperature and Pressure Safety:

- Many laboratory processes involving condenser tubes operate under high temperature and pressure. Regulations require that all equipment, including condenser tubes, be rated for the specific temperature and pressure conditions of their use.

- Safety relief mechanisms and regular maintenance checks are required to prevent accidents due to overpressure or temperature extremes.

- Training and Competency:

- Laboratory personnel must be properly trained in the use of condenser tubes, including their setup, operation, and emergency procedures. This training should be documented and regularly updated.

- Competency assessments are often required to ensure that personnel are capable of safely operating laboratory equipment, including condenser tubes.

- Waste Disposal and Environmental Compliance:

- Regulations require proper disposal of waste generated during experiments involving condenser tubes. This includes both chemical waste and broken glassware.

- Compliance with environmental regulations is also important, particularly in the disposal of hazardous materials and the minimization of environmental impact.

- Emergency Procedures and First Aid:

- Laboratories must have clear emergency procedures for accidents involving condenser tubes, including chemical spills, glassware breakage, and fires.

- First aid kits and equipment such as eyewash stations and safety showers must be readily accessible in the vicinity of the laboratory workspace.

Adhering to these safety standards and regulations is essential for the safe and effective use of condenser tubes in laboratory settings. They not only ensure the protection of laboratory personnel but also contribute to the reliability and accuracy of experimental results. Regular audits and updates of safety protocols are important to keep up with technological advancements and changes in safety regulations.

Environmental Considerations

While condenser tubes are essential in laboratory settings, it’s important to consider their environmental impact, particularly in terms of waste management and sustainability. The production, use, and disposal of condenser tubes can have various implications on the environment, which necessitates responsible practices.

- Material Usage and Sustainability:

- Condenser tubes, especially those made of borosilicate glass, are durable and can be reused extensively, reducing the need for frequent replacement and minimizing waste. The choice of materials like borosilicate glass also aligns with sustainability, owing to its longer lifespan and chemical resistance, which reduces the likelihood of contamination and waste.

- Energy Consumption:

- The production of glass condenser tubes requires significant energy, mainly in the form of high-temperature processes. Advancements in manufacturing technology can help in reducing this energy consumption, making the production process more environmentally friendly.

- In operation, condenser tubes themselves do not consume much energy, but the systems they are part of (like cooling systems) can be optimized for energy efficiency.

- Chemical Waste Management:

- During the cleaning of condenser tubes, the use of chemicals and solvents can result in waste that needs to be managed responsibly. It’s essential to follow proper disposal guidelines for these chemicals to prevent environmental contamination.

- Laboratories should implement waste reduction strategies, such as recycling solvents where possible and using environmentally friendly cleaning agents.

- Water Usage:

- Many condenser tubes require a continuous flow of water for cooling purposes, which can lead to significant water usage. Implementing water recycling systems or using closed-loop cooling systems can significantly reduce water waste.

- Disposal and Recycling:

- At the end of their lifecycle, proper disposal of condenser tubes is crucial. Glass tubes can often be recycled, reducing landfill waste. However, this depends on local recycling capabilities and facilities.

- In cases where condenser tubes have been used with hazardous materials, special disposal procedures must be followed to prevent contamination and harm to the environment.

- Promoting Green Laboratory Practices:

- Laboratories can adopt broader green practices, such as reducing overall material consumption, energy conservation, and minimizing the use of hazardous substances. These practices, along with responsible use and disposal of condenser tubes, contribute to a more sustainable and environmentally friendly scientific research environment.

In conclusion, while condenser tubes are indispensable in many laboratory processes, their environmental impact requires careful consideration. Through sustainable material choices, energy-efficient practices, responsible waste management, and water conservation, the environmental footprint of using condenser tubes can be minimized, contributing to the broader goal of sustainable science.

Technological Advancements and Future Trends

The field of condenser tube design has seen significant technological advancements in recent years, driven by the need for more efficient, durable, and environmentally friendly laboratory equipment. These developments not only enhance the performance of condenser tubes but also open new avenues for future innovations. Here’s a look at some of the recent advancements and potential future trends in this area.

- Material Innovations:

- Recent Advances: The use of advanced materials such as reinforced borosilicate glass and specialized polymers has increased the durability and chemical resistance of condenser tubes. Developments in surface treatments and coatings have also improved their thermal efficiency and reduced the likelihood of chemical adherence.

- Future Trends: Research into nanomaterials and composite materials could lead to condenser tubes with even greater heat transfer efficiency, chemical inertness, and mechanical strength.

- Design Optimization:

- Recent Advances: Computer-aided design (CAD) and computational fluid dynamics (CFD) have allowed for the optimization of condenser tube geometry, enhancing heat exchange efficiency and minimizing fluid resistance.

- Future Trends: The integration of smart design elements, such as adjustable geometries or self-cleaning surfaces, could make condenser tubes more adaptable to different laboratory processes and reduce maintenance requirements.

- Energy Efficiency:

- Recent Advances: The incorporation of energy-efficient cooling systems and the optimization of water usage in condenser tubes have been a focus, reducing the environmental footprint of laboratory operations.

- Future Trends: Further advancements in cooling technologies, such as the use of phase change materials or more efficient Peltier coolers, could enhance the energy efficiency of condenser tubes.

- Integration with Digital Technologies:

- Recent Advances: The integration of sensors and digital monitoring systems in condenser tubes allows for real-time tracking of temperature, flow rates, and other critical parameters, enhancing control over distillation and condensation processes.

- Future Trends: The advent of the Internet of Things (IoT) and machine learning could lead to fully automated condenser systems that optimize their operation in real-time based on data analytics.

- Sustainability and Environmental Impact:

- Recent Advances: Increased focus on sustainability has led to the development of condenser tubes that are more environmentally friendly, both in terms of materials used and operational efficiency.

- Future Trends: Research into alternative materials that are biodegradable or easier to recycle could further reduce the environmental impact of condenser tubes.

- Customization and Modular Design:

- Recent Advances: The move towards customizable and modular condenser tube designs allows for greater flexibility in laboratory setups, catering to a wide range of experimental needs.

- Future Trends: Continued innovation in modular design could lead to condenser tubes that are easily configurable for different applications, further enhancing their versatility.

In conclusion, the field of condenser tube technology is evolving rapidly, with advancements focusing on enhancing efficiency, reducing environmental impact, and integrating digital technologies. Looking ahead, we can anticipate a new generation of condenser tubes that are smarter, more adaptable, and more sustainable, aligning with the broader trends of technological innovation and environmental consciousness in scientific research.

Comparison with Alternative Methods

In laboratory settings, condenser tubes are not the only means of achieving cooling and condensation. Various other methods are employed, each with its own set of advantages and limitations. Understanding these alternatives and how they stack up against condenser tubes is crucial for selecting the right approach for specific laboratory tasks.

- Air Cooling:

- Advantages: Simple and doesn’t require any special equipment. It’s cost-effective and suitable for substances that condense at relatively higher temperatures.

- Limitations: Less efficient for substances with lower condensation points. It’s also slower compared to condenser tubes and can be ineffective in a hot laboratory environment.

- Refrigeration Units:

- Advantages: Provides controlled and consistent cooling, suitable for sensitive substances. Can achieve much lower temperatures than condenser tubes.

- Limitations: More expensive to install and operate. These units are also bulkier and require more maintenance.

- Immersion in a Cold Bath:

- Advantages: Simple and does not require complex setup. It’s versatile, as different cooling liquids can be used for different temperature requirements.

- Limitations: Not as efficient as condenser tubes for rapid cooling. Temperature control is less precise, and there’s a risk of contamination if the bath liquid is not carefully chosen.

- Peltier Coolers:

- Advantages: Offers precise temperature control and can cool down very quickly. It’s compact and can be integrated into various experimental setups.

- Limitations: Limited in the amount of heat they can dissipate. More suitable for small-scale applications and not as effective for large volume cooling.

- Dry Ice:

- Advantages: Very effective for rapid cooling. Can achieve very low temperatures quickly.

- Limitations: Handling dry ice requires caution due to its extreme cold. Its availability can be an issue, and it’s not suitable for prolonged cooling needs.

Compared to these methods, condenser tubes offer a balance of efficiency, control, and versatility. They are particularly effective for continuous cooling and condensation processes and are a staple in distillation and reflux operations. While alternatives like refrigeration units and Peltier coolers have their place in certain scenarios, condenser tubes remain the preferred choice for many standard laboratory procedures due to their simplicity, reliability, and ease of integration into various experimental setups.

Conclusion

Condenser tubes are not just laboratory apparatuses; they are gateways to scientific exploration and discovery. Their evolution, application, and technological advancements reflect the dynamism of scientific research. For laboratory enthusiasts, professionals, or anyone intrigued by the wonders of scientific experimentation, delving deeper into the world of laboratory equipment can be both enlightening and inspiring. For a comprehensive exploration of various laboratory tools and their applications, visit Glasswaree.com, your portal to the vast universe of laboratory instruments and innovations.