Have you ever wondered why your laboratory glassware withstands regular use, harsh chemicals, and occasional bumps with minimal damage? What makes these seemingly delicate items so resilient and long-lasting?

Lab glassware is not just any ordinary glass; it’s a marvel of material engineering, designed to resist wear and tear in challenging laboratory environments. Its resilience is crucial for reliable experiments and consistent results, a true hidden superpower in the world of science.

Maintaining this durability is essential for both safety and scientific accuracy.

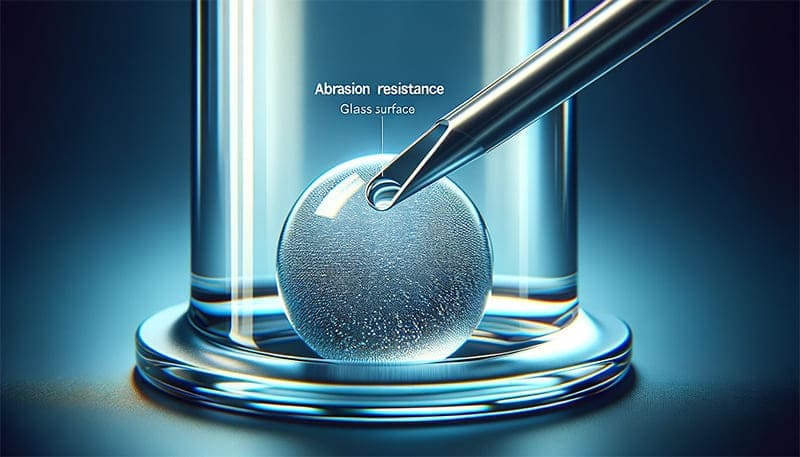

What is the Abrasion Resistance of Glassware

The abrasion resistance of glassware refers to its ability to resist mechanical forces such as friction, scratching, and impact during use. In laboratories, glassware is a common experimental apparatus, extensively used in fields like chemistry, biology, and medicine. Frequently coming into contact with various chemical reagents and samples, or needing long-term usage, the abrasion resistance of glassware is crucial for both its lifespan and the accuracy of experimental results.

Exploring the Resilience of Lab Glassware

What gives laboratory glassware its remarkable durability? Several factors play a role:

- Material Composition: Lab glass is typically made from borosilicate glass, known for its exceptional resistance to thermal shock and chemical corrosion. This type of glass comprises silica and boron trioxide, providing it with a low coefficient of thermal expansion and high chemical durability.

- Surface Treatments: Glassware undergoes various treatments to enhance its resistance to scratches and abrasions. Processes like annealing, tempering, and polishing not only increase its mechanical strength but also its resistance to chemical attacks.

- Manufacturing Techniques: The manufacturing process of laboratory glassware is meticulously controlled to ensure uniform thickness and shape, which contributes to its overall strength and durability.

In addition to these three factors, the manufacturing process of glassware often involves specific polishing and grinding techniques. These procedures are crucial as they further enhance the abrasion resistance of the glassware. Polishing smoothens the surface, reducing microscopic flaws that can lead to cracks or breaks under stress. Grinding, on the other hand, ensures that the surfaces are even and free from irregularities that might compromise the glassware’s structural integrity. Together, these processes play a pivotal role in ensuring the durability and reliability of lab glassware, especially under rigorous experimental conditions.

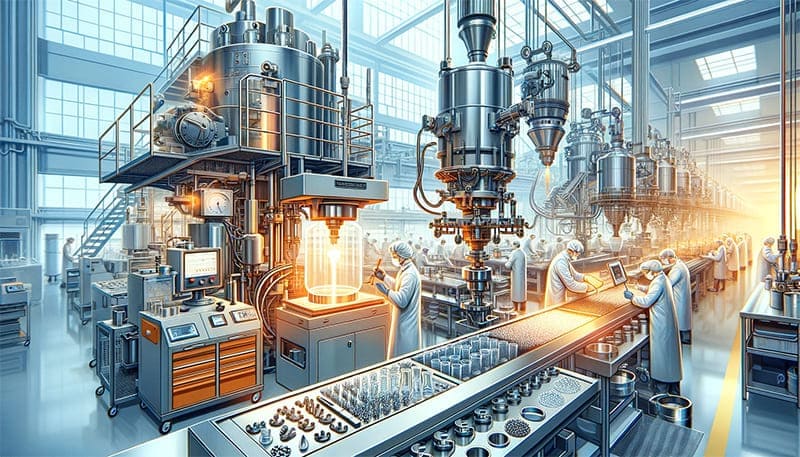

Ensuring Abrasion Resistance in the Production of Laboratory Glassware

To guarantee the abrasion resistance of laboratory glassware, stringent controls are necessary throughout the production process. These controls are crucial for maintaining the quality and durability of the glassware. Key aspects include:

- Quality of Raw Materials: The production starts with the selection of high-quality raw materials. For borosilicate glass, this means pure silica and boron trioxide. Any impurities in these materials can weaken the glass and reduce its abrasion resistance.

- Precise Mixing and Melting: The raw materials must be mixed in precise ratios and melted under controlled conditions. This ensures uniformity in the glass composition, crucial for its strength and resistance to wear and tear.

- Controlled Cooling and Annealing: After shaping, the glassware undergoes a controlled cooling process known as annealing. This step is vital to relieve internal stresses and prevent the formation of weak spots that could reduce abrasion resistance.

- Surface Treatment Monitoring: As mentioned, surface treatments like polishing and grinding are essential for enhancing abrasion resistance. The quality and uniformity of these treatments must be closely monitored. Proper polishing reduces surface flaws, and grinding ensures even surfaces, both contributing to the glassware’s durability.

- Regular Testing and Inspection: Throughout the production process, regular testing and inspection are imperative. This includes checking for consistency in thickness, detecting any surface imperfections, and conducting abrasion resistance tests. These quality checks help identify and rectify any issues before the glassware reaches the laboratory.

- Environmental Controls: The manufacturing environment should be controlled to avoid contamination and to maintain consistent production conditions. Temperature, humidity, and cleanliness are all factors that can influence the quality of the glassware.

By implementing these rigorous controls during production, manufacturers can ensure that the laboratory glassware not only meets the required scientific standards but also possesses the high abrasion resistance needed for prolonged and reliable use in laboratory settings.

Comparative Analysis of Abrasion Resistance in Different Laboratory Glassware Materials

Selecting the right material for laboratory glassware is a critical decision that hinges on understanding the abrasion resistance of various materials. This attribute is essential for ensuring the longevity and effectiveness of glassware in laboratory settings. The following table provides a comparative analysis of different materials used in laboratory glassware, focusing on their abrasion resistance, along with their typical applications and cost implications.

Comparing Abrasion Resistance of Different Materials in Laboratory Glassware

| Material | Abrasion Resistance | Key Characteristics | Typical Applications | Cost Comparison |

|---|---|---|---|---|

| Borosilicate Glass | High | High thermal and chemical resistance; low coefficient of thermal expansion. | High-temperature and chemical experiments. | Moderately Priced |

| Soda-Lime Glass | Moderate | Less expensive but more prone to thermal shock. | General lab use, less intensive applications. | Inexpensive |

| Quartz Glass | Very High | Excellent thermal and chemical resistance; withstands very high temperatures. | UV transparency, high-temperature processes. | Expensive |

| Lead Glass | Low to Moderate | Higher density and refractive index; used for radiation shielding. | Radiation shielding applications. | Moderately Expensive |

| Aluminosilicate Glass | High | Resistant to scratches and thermal shock. | High-strength, durable applications. | Moderately to Expensive |

| Polymer-based Glass | Variable | Ranges from low to high depending on the polymer; shatter-resistant. | Lightweight or shatter-resistant needs. | Variable |

Understanding these differences is key to choosing glassware that not only meets the specific needs of various laboratory experiments but also offers the best value and durability. The right choice of material can significantly enhance the longevity of glassware and, by extension, the reliability of experimental results. This table aims to provide a clear and concise guide for making such choices, balancing abrasion resistance with practicality and cost.

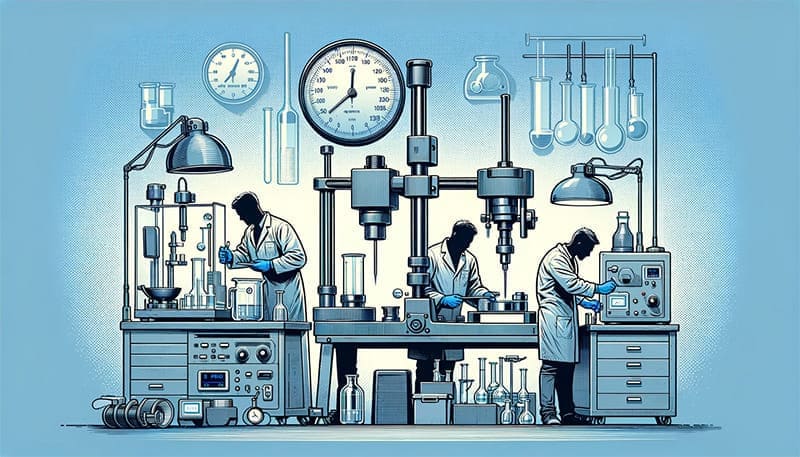

How is Glassware’s Resilience Tested?

Testing the abrasion resistance of glassware is crucial for assessing its lifespan and ensuring the accuracy of experimental results. Here are some methods to test the abrasion resistance of glassware:

- Hardness Test: Hardness is a key indicator of the abrasion resistance of glassware. A durometer can be used to test the surface hardness of the glassware. Generally, higher hardness indicates better abrasion resistance. During testing, it’s important to follow the durometer’s operating instructions to avoid inaccuracies due to excessive or insufficient test pressure.

- Scratch Test: Scratch testing assesses the glassware’s resistance to surface scratches. This involves applying pressure with a sharp, hard object, like a diamond pen or the probe of a hardness tester, on the glassware surface and then observing for scratches. The absence or minimal appearance of scratches indicates good abrasion resistance.

- Friction Test: Friction testing evaluates the abrasion resistance of the glassware surface when rubbed against other materials. This can be done by placing the glassware on a friction testing machine, setting certain numbers of friction cycles and speed, and then using a hard material like sandpaper to rub the glassware surface. The appearance of wear or scratches after the test is observed, along with recording the parameters like the number of friction cycles and speed.

- Impact Test: Impact testing assesses the glassware’s abrasion resistance when subjected to impact forces. The glassware is placed on an impact testing machine with a set impact energy and speed, and then the surface is impacted. After the impact, the presence of cracks or breakage on the glassware surface is observed, along with recording parameters like impact energy and speed.

- Environmental Test: Environmental testing evaluates the abrasion resistance of glassware under various environmental conditions. The glassware is exposed to conditions such as high or low temperatures, humidity, ultraviolet light, etc., and observed for signs of aging, discoloration, cracking, etc. The environmental conditions and duration of the test are recorded.

It’s important to note that different types of glassware have varying chemical compositions and physical properties, affecting their abrasion resistance. Therefore, when testing glassware for abrasion resistance, the appropriate testing methods and evaluation standards should be chosen based on the type and requirements of the glassware. For accurate results, the tests should be conducted in a controlled environment with consistent temperature and humidity, minimizing the influence of human factors.

In summary, testing the abrasion resistance of glassware involves considering multiple factors, including hardness, scratches, friction, impact, and environmental conditions. These tests provide a comprehensive assessment of the abrasion resistance and lifespan of glassware, ensuring the accuracy and reliability of experimental results and operations.

Understanding Wear Resistance in Everyday Use

In daily lab operations, glassware’s wear resistance translates to a longer lifespan and fewer replacements. This durability is particularly crucial in educational settings where equipment frequently handles a myriad of experiments and student use. The wear resistance ensures that the glassware can withstand not just the chemical reactions but also the physical handling, cleaning, and storage processes it undergoes regularly.

| Lab Glassware Item | Use in Laboratory | Reason for High Wear Resistance Requirement |

|---|---|---|

| Beakers | Mixing, heating, and storing chemicals | Regular exposure to heat and chemicals necessitates high thermal and chemical resistance. |

| Erlenmeyer Flasks | Titration, mixing solutions | Frequent shaking and mixing demand durability against mechanical stress. |

| Test Tubes | Holding small amounts of substances for reactions or heating | Repeated heating and cooling cycles require thermal shock resistance. |

| Burettes | Precise dispensing of liquids for titration | Constant handling and exposure to various chemicals call for chemical and mechanical durability. |

| Petri Dishes | Culturing microorganisms | Regular sterilization and exposure to biological materials need heat and chemical resistance. |

| Volumetric Flasks | Precise dilutions and solution preparation | Accuracy in measurements requires the glass to maintain its shape and integrity over time. |

| Pipettes | Transferring precise volumes of liquids | Frequent use and exposure to different chemicals necessitate high precision and chemical resistance. |

| Condensers | Distillation processes | Continuous exposure to heat and steam demands high thermal resistance and durability. |

| Graduated Cylinders | Measuring liquid volumes | Regular handling and washing require resilience to physical wear and tear. |

| Watch Glasses | Evaporation of liquids, holding solids | Exposure to heat and chemicals demands durability and thermal resistance. |

Balancing Durability with Care

While lab glassware is designed for durability, proper handling and maintenance are essential to maximize its lifespan. Simple practices like proper cleaning, avoiding extreme temperature changes, and storing glassware safely can significantly extend its usability. Moreover, understanding the limits of glassware’s resilience is crucial; even the most durable glass has its breaking point.

The Role of Resilience in Advanced Research

In cutting-edge research, the resilience of lab glassware plays a pivotal role. High-quality glassware that resists wear and tear contributes to the precision and accuracy of research outcomes. This reliability is particularly vital in fields like pharmaceuticals, biotechnology, and environmental science, where even minor contamination or variation can lead to significant deviations in results.

The Real-World Impact of Durable Lab Glassware

The durability of lab glassware has a significant impact on laboratory work:

- Safety: Stronger glassware reduces the risk of breakage, ensuring the safety of laboratory personnel.

- Accuracy and Consistency: Durable glassware maintains its shape and integrity over time, leading to more reliable experimental results.

- Cost-Effectiveness: Long-lasting glassware means fewer replacements, reducing the overall costs for laboratories.

- Environmental Impact: Less frequent replacements also mean reduced waste, contributing to environmental sustainability.

Conclusion

Discover the incredible resilience of laboratory glassware, a cornerstone of scientific innovation. Embrace this hidden superpower in your lab, where durability meets precision, ensuring safety and accuracy in every experiment. Join the community of scientists and educators who rely on the strength of lab glassware. Explore our comprehensive guide, enhance your laboratory practices, and push the boundaries of research with confidence. Don’t miss out on the secret to successful science – delve into the world of durable lab glassware now!