Have you ever wondered how the delicate-looking glassware in laboratories withstands intense pressure during experiments? Isn’t it intriguing to think about how these fragile items resist breaking under such conditions? How do scientists ensure the safety and reliability of these glass instruments?

Lab glassware is designed to withstand high-pressure environments, a crucial aspect of ensuring experimental accuracy and safety in scientific research. The secret to their high-pressure resistance lies in their material composition, design, and manufacturing process. This capability is essential in various scientific fields, from chemistry to biotechnology.

Understanding the importance of high-pressure resistance in lab glassware keeps researchers and experiments safe.

What Constitutes High-Pressure Resistance in Lab Glassware?

High-pressure resistance in lab glassware refers to its ability to withstand external pressure without breaking or deforming. In laboratories or industrial production, glassware often needs to endure certain levels of pressure, such as pressure generated during chemical reactions or the negative pressure from vacuum processes. In these scenarios, the glassware must have sufficient pressure resistance to avoid breakage or deformation, ensuring the smooth conduct of experiments or production processes.

The pressure resistance of glassware depends on several factors, including the chemical composition of the glass, its physical properties, manufacturing process, and thickness. Generally, borosilicate glass has better pressure resistance due to its higher hardness and lower brittleness. Additionally, the thickness of the glassware also impacts its pressure resistance, with thicker glassware having better resistance.

In laboratory or industrial settings, it’s crucial to select glassware with appropriate pressure resistance for the specific application and to be mindful of safety concerns during use. Additionally, avoiding exceeding the glassware’s pressure limits is vital to prevent accidents like breakage or deformation.

Key Factors Influencing the Pressure Resistance of Lab Glassware

Understanding the factors that influence the pressure resistance of laboratory glassware is crucial for ensuring its safe and effective use. Several specific factors play a significant role in determining how well glassware can withstand high pressures:

- Material Composition: The type of glass used is the most critical factor. Borosilicate glass, known for its durability and thermal resistance, is commonly used. Its unique composition, including silica, boron trioxide, and other elements, provides excellent resistance to thermal shock and mechanical stress.

- Glass Thickness: Thicker glass generally means higher pressure resistance. The wall thickness of glassware is designed according to its intended use. For high-pressure applications, glassware with thicker walls is used to prevent breakage.

- Manufacturing Quality: The quality of the manufacturing process significantly affects the glassware’s pressure resistance. Imperfections such as bubbles, streaks, or uneven thickness can create weak points that reduce the glassware’s ability to withstand pressure.

- Thermal Treatment: Annealing and tempering processes relieve internal stresses within the glass, enhancing its structural integrity. Properly annealed glassware is less likely to crack under pressure.

- Surface Condition: Scratches, chips, or any form of surface damage can significantly compromise the pressure resistance of glassware. Regular inspections are necessary to ensure the surface integrity of the glass.

- Design and Shape: The shape and design of the glassware play a crucial role. Designs that distribute stress evenly, such as rounded corners, are less likely to crack under pressure. Conversely, sharp angles and irregular shapes can create stress points that reduce pressure resistance.

- Usage History: Repeated heating and cooling, chemical exposure, and mechanical stress can degrade the glass over time, reducing its pressure resistance. Proper maintenance and timely replacement of glassware are essential.

- Seals and Joints: For glassware with stoppers or connectors, the quality of the seal or joint impacts its overall pressure resistance. Imperfect seals can be weak points under high pressure.

- Environmental Factors: External conditions like temperature and chemical exposure can influence the glass’s strength. For instance, exposure to corrosive chemicals can weaken the glass structure, thereby reducing its pressure resistance.

Understanding and addressing these factors are essential for ensuring that laboratory glassware is safe and effective for high-pressure applications. Regular inspections, proper handling, and choosing the right type of glassware for specific applications are crucial practices in any laboratory setting.

In conclusion, the pressure resistance of lab glassware is a complex interplay of material science, engineering, and careful handling. By considering these factors, researchers and lab technicians can ensure the safe and effective use of glassware in high-pressure environments, thereby safeguarding the integrity of their scientific work.

How is Glassware’s Pressure Resistance Tested?

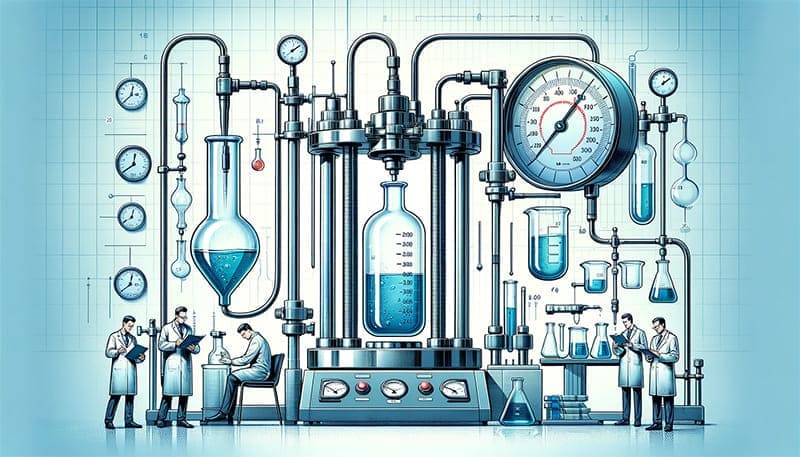

Testing the pressure resistance of glassware is crucial for ensuring its safety and reliability during use. Here are some methods for testing the pressure resistance of glass instruments:

- Direct Pressure Method: This involves adding water or another fluid to the glassware and then placing it in a pressure testing machine. The glassware is pressurized to a preset value using a pressurizing device, and this pressure is maintained for a period to observe whether there are any cracks, deformations, or similar issues. This method is suitable for testing the compressive strength and sealing performance of glass containers.

- Incremental Pressure Method: A certain amount of water or other fluid is added to the glassware, which is then placed in a pressure testing machine. The glassware is pressurized to a predetermined level, maintained for a while, and then rapidly depressurized to zero. Observations are made for any cracks or deformations. This method is useful for testing the pressure resistance and sealing performance of glass containers.

- Hydraulic Method: Similar to the direct pressure method, this involves adding water or another fluid to the glassware, which is then subjected to pressurization in a testing machine. The key difference is that the hydraulic method does not require placing the entire instrument in the pressure machine; instead, only the fluid inside the instrument is pressurized. This method is also suitable for testing the compressive strength and sealing performance of glass containers.

- Gas Pressure Method: An inert gas is added to the glassware, which is then placed in a pressure testing machine. The glassware is pressurized to a preset level and maintained for a time to check for any cracks or deformations. Unlike the direct pressure method, the gas pressure method uses gas as the pressurizing medium, which can better simulate actual usage conditions. This method is appropriate for testing the pressure resistance and sealing performance of glass containers.

During the testing process, the following points should be noted:

- The glassware should be thoroughly cleaned and dried before testing to avoid impurities and moisture affecting the results.

- Ensure the accuracy and stability of the pressurizing device during the test to avoid errors in the results.

- Observe changes in the glassware during testing. If cracks or deformations occur, stop the test immediately and record the results.

- After testing, carefully inspect and evaluate the glassware to determine if it meets usage requirements.

In summary, testing the pressure resistance of glassware is essential for ensuring its safety and reliability in use. Different testing methods are suitable for different types of glassware and usage scenarios, and the appropriate method should be chosen based on specific circumstances. Safety and accuracy are critical during the testing process to ensure the results are reliable and accurate.

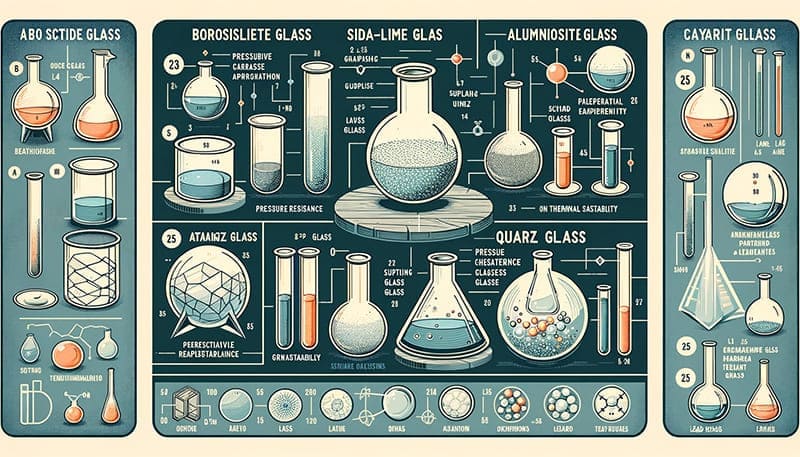

Comprehensive Comparison of Laboratory Glassware Materials

In the realm of scientific research, selecting the right type of glassware for laboratory use is crucial. The choice depends on several factors, including the material’s pressure resistance, thermal stability, and suitability for specific applications. This comprehensive table provides an overview of different types of laboratory glassware materials, comparing their key properties and ideal uses to guide researchers and laboratory technicians in making informed decisions.

| Material Type | Description | Pressure Resistance | Thermal Stability | Typical Thickness | Ideal Uses | Examples |

|---|---|---|---|---|---|---|

| Borosilicate Glass | Contains boron and silica. Resistant to thermal shock and chemical corrosion. | High | Very High | Medium to Thick | High-temperature applications, reactions involving sudden temperature changes, pressure applications. | Erlenmeyer flasks, Petri dishes |

| Soda-Lime Glass | Made from sodium carbonate and lime. Standard glass type. | Moderate | Moderate | Thin to Medium | General laboratory use, less intense chemical reactions, storage. | Beakers, test tubes |

| Quartz Glass | Made primarily of silica. Extremely high melting point. | Very High | Extremely High | Thin to Medium | UV applications, high-temperature processes, precise optical requirements. | UV spectroscopy cuvettes, high-temperature reaction vessels |

| Aluminosilicate Glass | Contains aluminum oxide. Higher resistance to chemical and thermal stress than borosilicate. | High | High | Medium to Thick | High-pressure environments, strong acids and bases, high-temperature applications. | High-pressure autoclaves, advanced reaction vessels |

| Lead Glass | Contains lead oxide. Higher refractive index. | Low to Moderate | Low | Thick | Radiation shielding, optical applications where clarity is not a priority. | Radiation shielding windows, certain types of lenses |

| Polymer-based Glassware | Made from plastics like Polycarbonate or Teflon. Unlikely to shatter. | Variable (Usually Low to Moderate) | Low to Moderate | Variable | Biological samples, less hazardous chemical handling, educational purposes. | Plastic storage bottles, flexible tubing |

This table highlights the diverse range of materials available for laboratory glassware, each with its unique set of properties and applications. Understanding these differences is key to ensuring the safety, efficiency, and success of laboratory operations.

It’s important to note that the selection of glassware in a laboratory setting depends on various factors including chemical compatibility, temperature requirements, and the specific nature of the experiments. Each material offers unique advantages and limitations, making it crucial to choose the appropriate type for specific laboratory needs.

Understanding these differences ensures safe and efficient laboratory operations, as well as the longevity and integrity of the glassware used in scientific research.

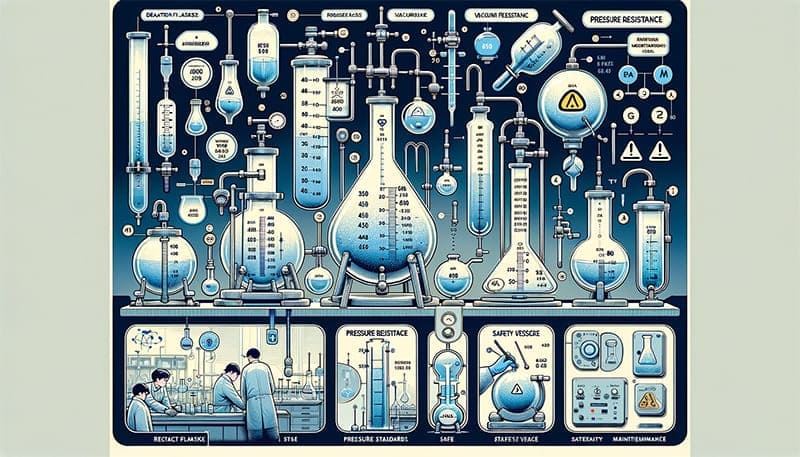

Detailed Guide to Pressure Resistance and Safety Standards in Laboratory Glassware

Choosing the right laboratory glassware is about more than just size and shape; it’s about understanding the specific pressure resistance requirements, safety standards, and material suitability for each type of glassware. This comprehensive guide provides an in-depth look at various types of laboratory glassware, detailing their pressure resistance requirements, standard references, recommended materials, safety tips, and maintenance needs. Such information is crucial for laboratory personnel to ensure both the integrity of their experiments and the safety of their working environment.

| Glassware Type | Description | Pressure Resistance Requirement | Standard or Regulation Reference | Material Recommendations | Safety Tips | Maintenance Requirements | Typical Use Cases |

|---|---|---|---|---|---|---|---|

| Reaction Flasks | Vessels for chemical reactions | High | ASTM E438, ISO 3585 | Borosilicate glass | Use in a fume hood; avoid sudden temperature changes | Regular inspection for cracks or chips | Chemical synthesis, reflux processes |

| Vacuum Flasks | Used for creating a vacuum inside | Very High | ASTM E1404 | Borosilicate or quartz glass | Avoid dropping; handle with care | Check for vacuum integrity regularly | Filtration, degassing liquids |

| Pressure Vessels | For reactions under pressure | Extremely High | ASME Boiler and Pressure Vessel Code | Aluminosilicate glass | Follow pressure limits; use safety shields | Pressure testing before each use | High-pressure reactions, supercritical fluid extractions |

| Distillation Columns | For separating liquid mixtures | Moderate to High | ISO 3839 | Borosilicate glass | Ensure proper setup and alignment | Clean after use; check for blockages | Distillation, purification processes |

| Graduated Cylinders | For measuring liquid volumes | Moderate | ASTM E1272 | Soda-lime or borosilicate glass | Avoid exposure to extreme temperatures | Regular calibration checks | Precise liquid measurement |

| Beakers | General-purpose glassware | Low to Moderate | ISO 3819 | Soda-lime glass | Do not use for reactions involving high pressure | Inspect for wear and tear | Mixing, heating, and storing liquids |

The effective selection and use of laboratory glassware require an understanding that goes beyond basic functionality. By adhering to the specified standards and guidelines, laboratory professionals can ensure they are using glassware that is not only fit for purpose but also maintains the highest levels of safety and reliability. This guide serves as a valuable resource for anyone involved in laboratory work, helping them make informed decisions about the glassware they use in their daily scientific endeavors.

Key Considerations for Using High-Pressure Resistant Glassware

Using high-pressure resistant glassware in laboratory settings is essential for conducting various scientific experiments and industrial processes safely. Understanding the limits of this glassware’s pressure resistance is crucial in preventing accidents and ensuring the integrity of the experimental results. Alongside acknowledging safety practices, such as wearing protective eyewear and avoiding contact with high temperatures or sharp objects, there are several additional considerations and measures to be taken into account.

1. Understanding Pressure Ratings: Before using any glassware, it’s vital to be aware of its specific pressure rating. This information, usually provided by the manufacturer, indicates the maximum pressure that the glassware can safely withstand. Exceeding this limit can lead to failures, such as cracks or shattering, which can be hazardous.

2. Regular Inspections: High-pressure glassware should be inspected regularly for any signs of wear, damage, or structural weakness. Even minor defects can significantly compromise the glassware’s integrity under high pressure. Look for scratches, chips, or etching marks that could indicate weaknesses.

3. Proper Handling and Storage: Glassware should be handled with care to avoid impacts or stresses that might weaken its structure. When not in use, store it in a safe, stable environment where it is protected from potential damage.

4. Gradual Pressure Changes: When using high-pressure glassware, it is advisable to change the pressure gradually. Sudden changes can cause stress on the glass, increasing the risk of failure. This is particularly important when heating or cooling glassware, as rapid temperature changes can also induce stress.

5. Use of Safety Shields: In scenarios where glassware is used under high pressure, employing safety shields can provide an additional layer of protection against accidental breakage. These shields can help contain the glass and chemicals in case of a glassware failure.

6. Training and Awareness: Laboratory personnel should be adequately trained in the proper use of high-pressure glassware. This training should include understanding the risks involved, knowing the pressure limits of the glassware, and being familiar with emergency procedures in case of glassware failure.

7. Compatibility with Chemicals: Ensure that the glassware is chemically compatible with the substances being used. Certain chemicals can react with the glass, weakening it and making it more susceptible to pressure-induced failure.

8. Proper Cleaning and Maintenance: Regular cleaning and maintenance of glassware are essential. Residues from previous experiments can cause unexpected reactions or stress points in the glass. Always follow the recommended cleaning procedures and check for any residual chemicals before using the glassware.

The safe use of high-pressure resistant glassware in laboratories hinges on a thorough understanding of its pressure capabilities, regular inspections, careful handling, gradual pressure changes, use of safety equipment, and proper training. By adhering to these practices and being vigilant about the glassware’s condition and limits, laboratory personnel can significantly reduce the risk of accidents and ensure the smooth progress of their experiments and industrial processes.

Advanced Safety Practices for High-Pressure Lab Glassware

In the intricate world of laboratory research, the use of high-pressure resistant glassware is a common necessity. “Advanced Safety Practices for High-Pressure Lab Glassware” delves into the critical measures and considerations essential for maintaining a secure and efficient laboratory environment, specifically when handling glassware designed to withstand significant pressure.

1. Understanding the Role of Seals and Closures: The integrity of high-pressure resistant glassware is not solely dependent on the glass itself; the quality of its seals and closures plays a vital role. In many laboratory applications, glassware needs to be sealed, either to maintain a vacuum or to contain reactions under pressure. The type and quality of these seals are paramount. For instance, ground glass joints are often used for their tight fit, but they must be checked for compatibility and wear. Using high-quality, pressure-resistant closures like PTFE (Teflon) or other polymer-based materials can ensure a better seal and enhance the overall pressure resistance of the system. Regular inspections for any signs of wear, corrosion, or damage to these components are just as crucial as inspecting the glassware itself.

2. Emergency Response Planning: Preparing for potential glassware failures under high pressure is a critical safety measure. Laboratories should have a clear and concise emergency response plan outlining the steps to be taken in the event of glassware breakage or failure. This plan should include immediate shutdown procedures, steps for containing any spills or chemical releases, and evacuation protocols. Additionally, all laboratory personnel should be trained in first aid measures, especially in handling cuts or exposure to hazardous chemicals. Regular drills and training sessions can help ensure that everyone knows how to act swiftly and safely in case of an emergency.

3. Record Keeping and Documentation: Consistent record-keeping is a vital aspect of laboratory safety and efficiency, especially when dealing with high-pressure glassware. Maintaining detailed records of each piece of glassware – including its pressure rating, purchase date, usage history, and any incidents of damage or failure – can provide valuable data for safety audits and help in making informed decisions about when to retire or replace glassware. These records also assist in identifying trends or recurrent issues with specific types of glassware or experiments, which can lead to improvements in laboratory protocols and equipment choices.

Incorporating these additional measures into the use of high-pressure resistant glassware significantly enhances safety and reliability in laboratory environments. By understanding the importance of seals and closures, preparing for emergencies, and keeping detailed records, laboratories can maintain a high standard of safety while conducting complex and high-pressure experiments. These practices are not just about complying with safety norms but are integral to fostering a culture of responsibility and vigilance in scientific research.

Conclusion

Embracing the world of high-pressure resistant lab glassware opens doors to safer and more efficient scientific explorations. It calls for a blend of knowledge, vigilance, and adherence to safety practices. Remember, the right glassware is not just about what it holds, but also about holding its ground under pressure. Let’s continue to prioritize safety, stay informed, and push the boundaries of science with confidence and caution.